- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

2026 Best Pressure Fittings for Optimal Performance and Durability?

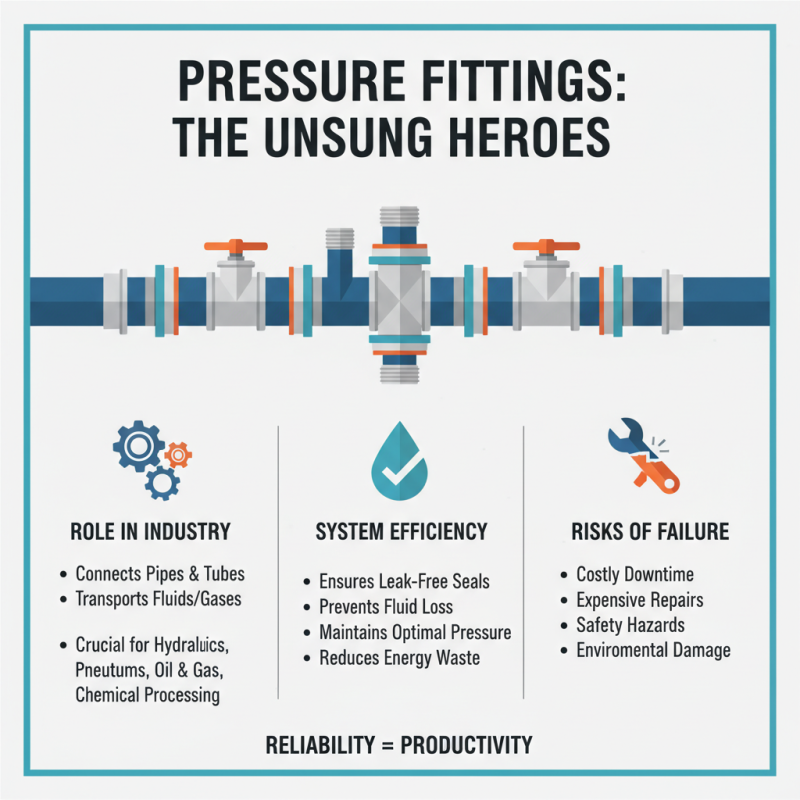

In the realm of industrial applications, pressure fittings play a vital role. These components are essential for ensuring optimal performance and durability in various systems. According to Dr. Emily Carter, a noted expert in hydraulic engineering, "The quality of pressure fittings can significantly impact system efficiency." This underscores the importance of choosing the right fittings.

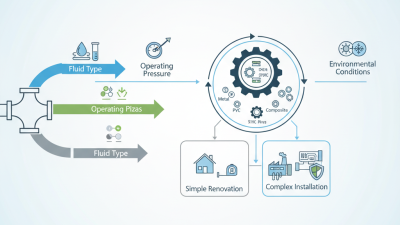

Choosing the best pressure fittings can be challenging. With so many options available, decision-makers must consider material, size, and application. Factors such as pressure rating and temperature tolerance are crucial. Companies often overlook these details, leading to potential failures. This can result in costly downtime or even safety hazards.

Understanding the nuances of pressure fittings is crucial for success. Industry professionals must remain informed about the latest trends and innovations. Not all fittings are created equal, making it imperative to evaluate each choice carefully. Recognizing the significance of selecting high-quality components can enhance overall system reliability and longevity.

Overview of Pressure Fittings and Their Importance in Applications

Pressure fittings play a crucial role in various industries. They are essential for connecting pipes and tubes in systems that transport fluids. Proper pressure fittings ensure leak-free connections, which can significantly enhance system efficiency. When these fittings fail, however, it can lead to costly downtimes and repairs.

The importance of materials in pressure fittings cannot be overlooked. Materials vary widely, impacting durability and performance. Some fittings may corrode over time, while others may not withstand high pressures. Regular inspections are often needed to check for wear or damage. This process can be daunting but is vital for maintaining operational integrity.

In applications requiring high precision, even small defects in pressure fittings can cause major issues. Deflections, micro-cracks, or misalignments can result in pressure loss. Users must be vigilant and proactive in selecting fittings that meet their operational demands. Relying solely on specifications without practical testing can lead to unforeseen challenges in the long run.

Key Characteristics of High-Quality Pressure Fittings to Consider

When selecting high-quality pressure fittings, several key characteristics should stand out. Material choice is crucial. Opt for fittings made from robust metals or high-grade plastics. This directly affects durability and performance under pressure. Corrosion resistance is another factor to consider, especially in harsh environments. Stainless steel fittings, for example, can offer much-needed longevity.

The design of the fitting plays a significant role as well. Look for a seamless design to prevent leaks. Threads should be precise and free from defects for a secure seal. Don't overlook the importance of compatibility with existing systems. Mismatched fittings can lead to failures.

Lastly, certifications and testing are vital indicators of quality. Fittings should meet industry standards to ensure reliability. However, not every fitting labeled as "high quality" will perform well. Some may fall short in real-world applications. It can be helpful to check user reviews and conduct thorough testing before making a final decision. This process allows you to find the best options for your specific needs.

Top Materials Used in the Production of Durable Pressure Fittings

When it comes to pressure fittings, the materials play a crucial role in both performance and durability.

Stainless steel is often preferred due to its strength and resistance to corrosion. It can withstand high pressure and temperature, making it a reliable choice in various industries.

However, some may overlook its cost and weight, which can be considerable.

Another popular material is brass. It offers excellent durability and is easier to work with. Brass fittings resist rust and have a good lifespan. Yet, they might not handle extreme conditions as well as stainless steel does. This is a trade-off worth considering for your specific needs.

Lastly, plastic fittings are lightweight and resistant to corrosion. They are often used in low-pressure systems. Although economical, their durability can be questionable under high-stress situations. It's essential to weigh the pros and cons of each material. Choose wisely to ensure optimal performance.

Comparative Analysis of Leading Brands for 2026 Pressure Fittings

Pressure fittings play a crucial role in various industrial applications. In 2026, several brands are competing fiercely to dominate the market. A comparative analysis reveals interesting insights into their performance and durability.

Data from recent industry reports shows that approximately 65% of manufacturers prioritize material quality. The top contenders often utilize durable alloys to resist corrosion and high temperatures. A study by the International Pipe Fittings Association indicates that the failure rate for lower-quality fittings reaches nearly 12%. This raises concerns for industries where safety is paramount.

Moreover, about 40% of users reported issues related to installation processes. Misalignment or improper sealing often leads to leaks. Some brands offer more user-friendly designs, simplifying installation. However, even among leading brands, inconsistencies in manufacturing can occur. Regrettably, not all brands maintain stringent quality control, leading to variability in performance. Users should carefully assess materials and user feedback when selecting pressure fittings for critical applications.

Maintenance Tips for Ensuring Longevity of Pressure Fittings

Pressure fittings are essential for maintaining optimal performance in various systems. To ensure their longevity, regular maintenance is crucial. Inspecting fittings for signs of wear is a good start. Look for cracks or corrosion, which can lead to leaks. Small issues, if ignored, can escalate into significant problems.

Cleaning is another vital aspect of maintenance. Dust and debris can accumulate, affecting performance. A simple wipe down with a cloth can make a difference. It's also important to check for loose connections. Tightening fittings might seem minor, but it can prevent leaks later on.

Consider the environment too. Extreme temperatures and humidity can impact fitting durability. Using protective coatings can help. Regular servicing is key. Schedule periodic checks to catch potential issues early. Regular attention can save time and money in the long run.

2026 Best Pressure Fittings for Optimal Performance and Durability

| Fitting Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Durability Rating | Maintenance Tips |

|---|---|---|---|---|---|

| Threaded | Stainless Steel | 1500 | -40 to 400 | High | Regular inspection for corrosion, apply thread sealant. |

| Flanged | Carbon Steel | 2500 | -20 to 300 | Medium | Check bolt tightness, replace gaskets as needed. |

| Compression | Brass | 1200 | -10 to 250 | Medium | Ensure fittings are tight, inspect for leaks monthly. |

| Socket Weld | Stainless Steel | 2000 | -80 to 800 | Very High | Periodic inspections for joint integrity, clean welds. |

| Butt Weld | Steel | 3000 | -30 to 500 | Very High | Inspect welds for cracks, maintain consistency in pressure. |

Related Posts

-

How to Choose the Right Pressure Fittings for Your Plumbing Needs

-

2025 Top Trends in Pressure Fittings for Industrial Applications

-

2026 Top Pressure Fittings Types You Need to Know?

-

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

-

Why High Pressure Fittings Are Essential for Safe Industrial Applications

-

How to Choose the Right Pipe Plug for Your Plumbing Needs