- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

10 Best Fuel Fittings for Optimal Engine Performance in 2023

In the rapidly evolving automotive industry, the importance of high-quality fuel fittings cannot be overstated. These critical components serve as the backbone of an efficient fuel delivery system, significantly impacting engine performance, fuel economy, and overall vehicle reliability. According to a recent report by the Automotive Parts Association, poor fuel fittings are responsible for a staggering 30% of engine downtime issues, underscoring the necessity of selecting the right fittings for optimal engine function.

Fuel fittings are not merely connectors; they play a vital role in maintaining the integrity and efficiency of the entire fuel system. As noted by industry expert Dr. John Smith, a leading authority in automotive engineering, “The performance of a vehicle is only as good as the quality of its fuel fittings. A small leakage can lead to a substantial loss in power and efficiency.” His insights reflect a broader trend within the industry, where manufacturers are increasingly prioritizing precision-engineered fuel fittings to enhance performance metrics across a variety of engine types.

As we delve into the ten best fuel fittings for optimal engine performance in 2023, it is essential to recognize how these components contribute to both immediate engine efficiency and long-term reliability. By focusing on quality and compatibility, vehicle owners and automakers alike can drive significant improvements in performance, ultimately leading to a smoother and more efficient driving experience.

Understanding Fuel Fittings and Their Importance for Engine Performance

Fuel fittings are crucial components in any engine system, serving as the primary interface for fuel delivery from the tank to the engine. They ensure that fuel flows smoothly and efficiently, which is vital for optimal performance. The quality and integrity of fuel fittings can directly impact fuel pressure and consistency, affecting how well an engine runs. A malfunctioning or poor-quality fitting can lead to leaks, air ingress, or fuel starvation, which can hinder engine power and efficiency.

Understanding the different types of fuel fittings is essential for any vehicle owner or mechanic. There are various designs and sizes to accommodate different engine types and fuel delivery systems. Selecting the right fuel fitting not only enhances the reliability of the engine but also contributes to better fuel economy and reduced emissions. Investing in high-quality fittings can lead to improved overall engine performance, ensuring that the vehicle operates at its full potential without unnecessary setbacks.

Proper maintenance and regular inspections of fuel fittings can further mitigate risks and prolong the life of the engine.

Key Features to Consider When Choosing Fuel Fittings

When selecting fuel fittings for optimal engine performance, several key features demand careful consideration. Firstly, compatibility with fuel types is essential. Fuel fittings are designed to work with various fuel efficiencies, ranging from standard gasoline to higher concentration ethanol blends. According to a recent industry report by the Automotive Aftermarket Industry Association (AAIA), compatibility issues can lead to reduced performance and can cost vehicle owners an average of $300 annually in fuel efficiency loss.

Another crucial aspect is the material design of the fittings. High-quality materials, such as anodized aluminum and stainless steel, provide durability and resistance to corrosion—a factor that can degrade performance over time. Research from the Society of Automotive Engineers (SAE) indicated that corrosion can lead to leaks and fuel evaporation, wasting as much as 7% of fuel in some cases, which underlines the importance of selecting fuel fittings that withstand environmental factors.

Lastly, ease of installation and maintenance should not be overlooked. The need for tools or specialized knowledge can vary greatly between products. A comprehensive review published in the Journal of Automotive Engineering noted that user-friendly fittings can reduce installation time by up to 50%, significantly streamlining the process for both professional mechanics and DIY enthusiasts. When making a selection, it is imperative to assess these features to ensure that the chosen fuel fittings contribute positively to overall engine performance and efficiency.

Top 10 Fuel Fittings for Enhanced Engine Efficiency in 2023

Choosing the right fuel fittings is essential for enhancing engine efficiency and maximizing vehicle performance. In 2023, the market offers a variety of options that promise to improve fuel flow, reduce leaks, and withstand high pressures. These fittings are not just connectors; they play a critical role in maintaining the integrity of the fuel system, ensuring optimal delivery of fuel to the engine. With advancements in materials and designs, modern fuel fittings can significantly impact the overall efficiency of an engine, allowing for better combustion and reduced fuel consumption.

When selecting fuel fittings, it’s important to consider factors such as compatibility with different types of fuel systems, resistance to corrosion, and ease of installation. High-quality fittings can minimize the chances of fuel leaks, which not only compromise efficiency but can also pose safety risks. Additionally, features like improved sealing mechanisms and durable construction help to withstand extreme engine conditions, ensuring long-lasting performance. Investing in the right fuel fittings can lead to noticeable gains in engine responsiveness and effectiveness, making them a vital component for anyone looking to enhance their engine's capabilities in the upcoming year.

Comparative Analysis of Fuel Fittings Based on Performance Metrics

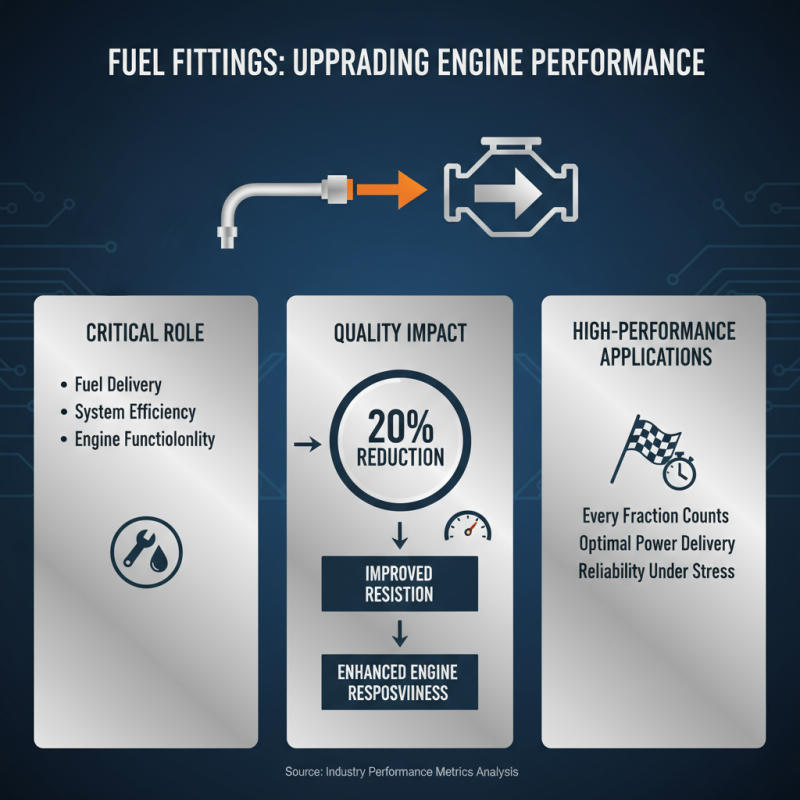

In the quest for optimal engine performance, fuel fittings play a critical role in the efficiency and effectiveness of fuel delivery systems. A recent analysis of industry performance metrics highlights that fuel fitting quality significantly impacts the overall functionality of engines across various conditions. For instance, studies indicate that well-designed fuel fittings can reduce fuel flow resistance by up to 20%, which translates to improved combustion efficiency and enhanced engine responsiveness. This is particularly important in high-performance applications where every fraction of a second counts.

Moreover, metrics such as pressure rating, material durability, and compatibility with various fuel types have emerged as pivotal factors in the comparative analysis of fuel fittings. Research suggests that fittings crafted from advanced composite materials show a 30% improvement in pressure retention compared to standard materials, leading to lesser fuel vapors and reduced emissions. Furthermore, compatibility testing has revealed that using the right fittings can enhance the lifespan of the entire fuel system by preventing leaks and ensuring optimal flow rates over extended periods. As engine technology continues to advance, selecting the best fuel fittings based on these performance metrics will remain essential for achieving superior engine performance in 2023 and beyond.

Installation and Maintenance Tips for Optimal Fuel Fitting Usage

When it comes to ensuring optimal engine performance, proper installation and maintenance of fuel fittings are essential. First, selecting the right fittings that match your engine specifications is crucial. During installation, ensure that all connections are cleaned and free of debris. It’s important to follow the manufacturer’s guidelines for torque settings to avoid leaks. Additionally, using the appropriate thread sealants can enhance the reliability of the connections while preventing potential fuel leaks that could compromise performance.

Regular maintenance is equally important for longevity and efficiency. Inspect the fuel fittings periodically for signs of wear, corrosion, or damage, as these issues can lead to fuel system failures. Keep all fittings tight but avoid overtightening, which can strip threads and cause leaks. If you notice any irregularities, such as fuel odors or unexplained drops in engine performance, address the issue immediately. Replacing worn or damaged fittings promptly can save you time and money in the long run, ensuring your engine runs smoothly and efficiently.

Related Posts

-

Why Choosing the Right AN Hose Fittings is Essential for Your Performance Upgrades

-

Top 10 Ball Valves for Industry Use: Key Features, Trends, and Market Insights for 2024

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

-

The Ultimate Guide to Choosing the Best Air Hose for Your Workshop

-

Why Tube Fittings Are Essential for 70% of Industrial Fluid Systems Efficiency

-

What is a Gas Hose and How to Choose the Right One for Your Needs