- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

Top 10 Best Fuel Fittings for Optimal Performance and Reliability

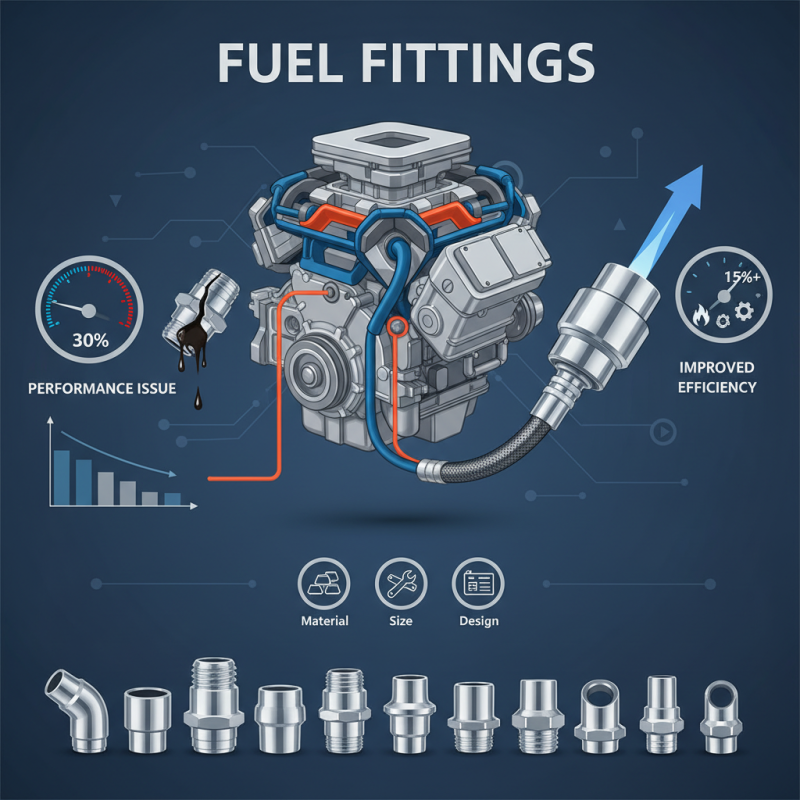

In the world of automotive engineering, fuel fittings play a pivotal role in performance and reliability. According to industry reports, up to 30% of performance issues in vehicles can be traced back to subpar fuel fittings. These critical components are designed to connect the fuel system to various engine parts. A faulty fitting can lead to fuel leaks, decreased efficiency, and engine malfunctions.

High-quality fuel fittings enhance vehicle performance significantly. Data shows that using premium fittings can improve fuel flow by over 15%. This is vital for maintaining engine efficiency and overall vehicle health. However, not all fittings are created equal. Many aftermarket options may not meet stringent industry standards, posing risks to performance and safety.

Choosing the right fuel fittings requires careful consideration. Factors such as material, size, and design can greatly influence your vehicle's efficiency. While some may overlook these details, ensuring optimal fittings is essential. The wrong choice can have lasting effects on your engine's performance and reliability. This guide will explore the top ten fuel fittings available, focusing on those that guarantee both efficiency and dependability.

Understanding Fuel Fittings: Importance in Engine Performance

Fuel fittings are crucial components in any engine system. They connect various parts, ensuring fuel flows smoothly. A small problem in these fittings can lead to significant issues. Leaks, blockages, or corrosion can disrupt engine performance. When fuel supply is inconsistent, the engine may misfire or stall. Proper fuel fittings can maintain optimal pressure and flow.

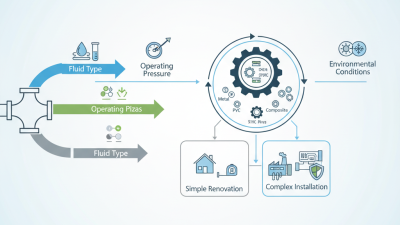

Choosing the right fuel fittings involves understanding their specific role. Each fitting type serves a different purpose. Some are designed for high pressure, while others accommodate low pressure. Knowing this can prevent costly mistakes. Regular inspections can reveal wear and tear. Over time, fittings can degrade, affecting overall efficiency. Ignoring these components may lead to larger engine problems.

Attention to detail is essential. Even a minor fitting issue can impact performance. Ensure all connections are tight and free of debris. It’s easy to overlook these small parts, but they are vital. Investing in high-quality fittings is a step towards reliability. A neglected fitting may seem insignificant but can cause substantial damage. Awareness of this can lead to better maintenance practices.

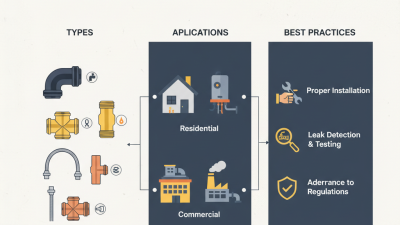

Types of Fuel Fittings and Their Applications

Fuel fittings play a crucial role in ensuring the reliable performance of any fuel system. There are various types of fuel fittings tailored for specific applications. Common types include hose fittings, quick disconnects, and connector fittings. Each type serves unique functions, helping to maintain efficiency in fuel delivery.

Hose fittings are essential in connecting hoses to pumps or tanks. They come in various sizes and shapes to match different systems. Quick disconnects ensure rapid fuel line connections, ideal for maintenance tasks or emergencies. Connector fittings help join different sections, allowing for flexibility in fuel lines.

Tips: Always choose the right fitting for your system's specifications. An ill-fitting connector can lead to leaks or even catastrophic failures. Regularly inspect your fittings for wear and tear. This can prevent costly downtime.

Industry reports show that improper fittings can lead to a 30% decrease in system efficiency. Performance declines can often be traced back to incompatible fittings. It's essential to verify compatibility and maintain quality standards in every fuel application. Stay informed about the latest advancements in fuel fitting technology to ensure optimal reliability.

Key Features to Look for in High-Quality Fuel Fittings

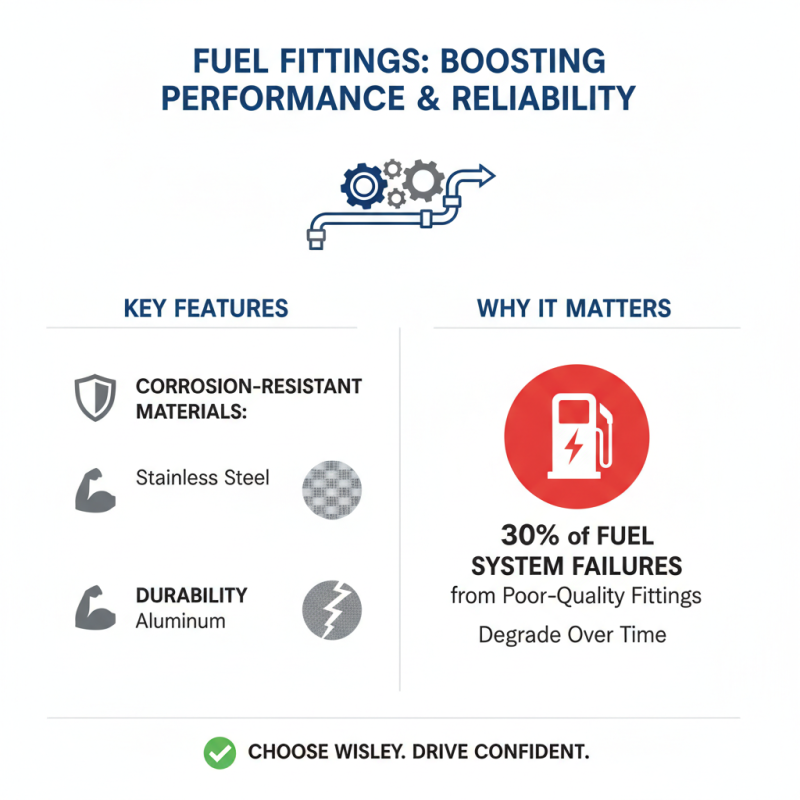

When selecting fuel fittings, certain key features can significantly enhance performance and reliability. Look for materials that resist corrosion. Stainless steel and aluminum fittings are popular for their durability. Reports indicate that up to 30% of fuel system failures stem from poor-quality fittings that degrade over time.

Sealing ability is another critical factor. O-rings and gaskets play a vital role in preventing leaks. A study found that nearly 20% of fuel leaks are attributed to compromised sealing materials. Ensuring the right fit and seal can save on costly repairs.

Tips: Always verify compatibility between the fitting and your fuel system. Even small discrepancies can lead to major issues. Regular inspections are essential. Remind yourself to inspect your fittings at least twice a year. Look out for signs of wear or damage, as these can develop unnoticed over time.

Top Brands for Fuel Fittings: A Comparative Overview

When considering fuel fittings, it's essential to explore various brands for performance and reliability. Each brand offers different materials and designs. Some focus on metal fittings, while others use advanced plastics. The choice impacts durability and efficiency.

In a comparative overview, one can notice inconsistencies in performance among popular brands. Some fittings might not withstand high-pressure environments. Others could corrode or degrade more quickly than expected. This variability can lead to unforeseen issues. Careful evaluation is necessary, as not every fitting meets all requirements.

Additionally, user reviews often reveal mixed experiences. For some, a brand that promises reliability may fall short in real-world applications. Observing these trends can guide better purchasing decisions. Ultimately, understanding the strengths and weaknesses of each option is crucial for optimal performance in the long run.

Installation and Maintenance Tips for Fuel Fittings

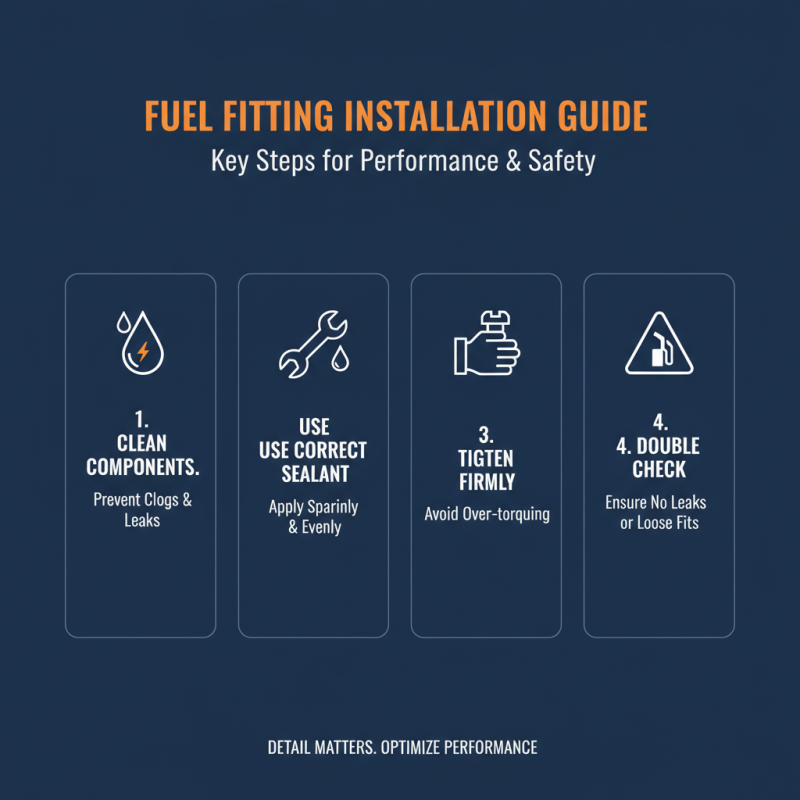

When installing fuel fittings, attention to detail is crucial. Start by ensuring all components are clean and free of debris. This prevents clogs and leaks, which can lead to performance issues. Use the right sealant for your fittings. Over or under-applying sealant can cause problems. Tightening should be firm but not excessive. Over-tightening may damage threads.

Regular maintenance keeps fuel fittings functioning well. Check for leaks regularly. A small leak can evolve into a major issue. Inspect hoses for wear and tear; they can degrade over time. Consider replacing them if they appear cracked or frayed. Avoid using fittings that are corroded or uneven. They compromise system reliability.

Always have the necessary tools on hand. Sometimes, having the right wrench makes all the difference. Understand that not all installations go perfectly. Learn from mistakes. If a fitting doesn’t seal correctly, reassess the installation process. Take time to reflect on what went wrong. Each experience helps improve your skills for future tasks.

Related Posts

-

10 Best Fuel Fittings for Optimal Engine Performance in 2023

-

How to Choose the Right Pressure Fittings for Your Plumbing Needs

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

2025 Top Trends in Pressure Fittings for Industrial Applications

-

2025 Top Gas Pipe Fittings Essential Guide for Homeowners and Professionals

-

How to Choose the Right Tube Fittings for Your Plumbing Projects