- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

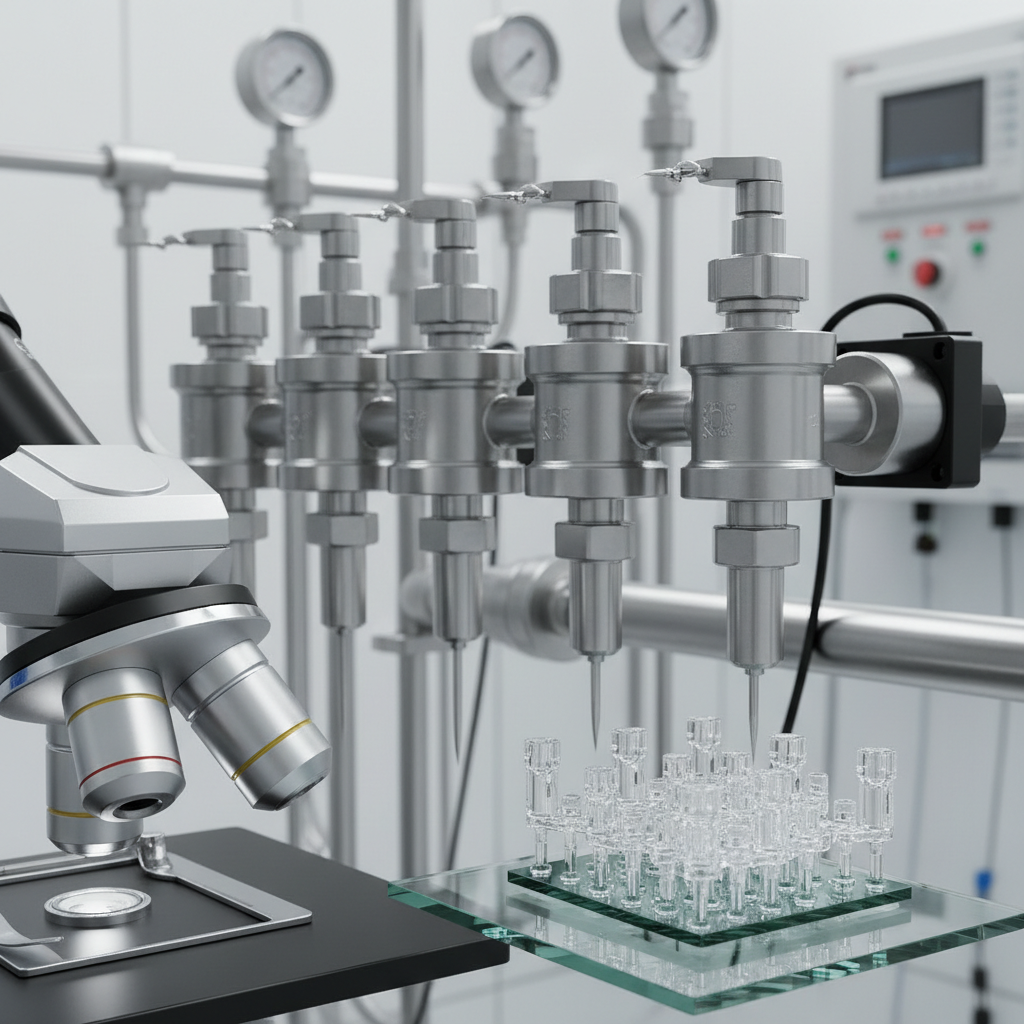

10 Best Needle Valves for Precision Control in Fluid Systems

In the ever-evolving landscape of fluid control systems, the importance of precision-engineered components cannot be overstated. Among these critical components, needle valves have emerged as a cornerstone for achieving accurate flow regulation in a variety of applications, ranging from industrial processes to intricate laboratory setups. According to a recent report by the Fluid Control Industry Association, the needle valve market is projected to witness a compound annual growth rate (CAGR) of 6.2% from 2023 to 2028, underscoring the increasing demand for these essential tools.

Renowned industry expert Dr. Emily Carter, a leading figure in fluid dynamics research, emphasizes the significance of needle valves in modern engineering. She states, "The precise control offered by needle valves is indispensable in achieving optimal performance and reliability in fluid systems." This sentiment reflects the growing recognition of needle valves as not just mechanical components, but as vital instruments that enhance the efficiency of entire systems. As we delve into the 2025 top 10 needle valves, we explore the finest examples available, highlighting their unique features and applications to help professionals make informed decisions in their fluid control endeavors.

Top Features to Look for in Precision Needle Valves

When selecting precision needle valves for fluid systems, several key features should be prioritized to ensure optimal performance. First, look for valves with high-quality materials such as stainless steel or brass, which provide durability and resistance to corrosion. The construction should allow for fine adjustments, enabling precise control over flow rates. Additionally, the presence of a soft-sealing mechanism can prevent leaks, enhancing reliability in sensitive applications.

Another important feature is the valve's pressure and temperature ratings. Ensure the needle valve can withstand the specific operating conditions of your fluid system. Compatibility with various fluids, including aggressive chemicals, is also critical. Finally, consider the valve’s size and connection types to ensure integration into your existing system is seamless. These features collectively contribute to the overall efficacy and longevity of precision needle valves in managing fluid flow.

Comparative Analysis of Materials Used in Needle Valve Construction

The construction materials used in needle valves play a critical role in their performance and reliability within fluid systems. A comparative analysis reveals that the choice of materials, such as stainless steel, brass, and various polymers, directly impacts the valve's ability to withstand pressure, temperature fluctuations, and corrosive environments. Stainless steel offers outstanding strength and corrosion resistance, making it suitable for high-pressure applications, while brass provides a cost-effective alternative for lower pressure systems. Polymers, on the other hand, are often utilized in applications where weight savings and chemical resistance are paramount.

Recent studies, including numerical and experimental investigations into the characteristics of electronic expansion valves, underscore the importance of having precise control mechanisms like needle valves in fluid systems. These valves not only regulate flow but also help mitigate issues such as cavitation and noise, which can be detrimental to system performance. As the industrial valve market continues to evolve, focusing on material advancements will be vital in enhancing the efficiency and durability of needle valves, thus contributing significantly to overall fluid dynamics management.

10 Best Needle Valves for Precision Control in Fluid Systems - Comparative Analysis of Materials Used in Needle Valve Construction

| Valve Model | Material | Size Range (inch) | Pressure Rating (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Model A | Stainless Steel | 1/4 - 1 | 1500 | -60 to 400 | Chemical Processing |

| Model B | Brass | 1/8 - 3/4 | 1000 | -20 to 250 | Water Supply |

| Model C | Plastic | 1/4 - 1 | 300 | -40 to 180 | Food Industry |

| Model D | Copper | 1/4 - 2 | 1200 | -20 to 350 | Oil and Gas |

| Model E | Titanium | 1/8 - 1 | 2000 | -50 to 600 | Aerospace |

Applications of Needle Valves in Various Fluid Control Systems

Needle valves have become essential components in various fluid control systems due to their precision and reliability. Their applications range from microfluidic technologies, where highly efficient passive valves are needed to manage low flow rates, to industrial settings that demand robust solutions for gas and liquid management. With the industrial valve market showcasing different types, including needle valves, the global demand for effective fluid control solutions continues to grow. According to recent industry reports, the needle valve segment is particularly fueled by advancements in automation and increased efficiency standards, highlighting a projected growth rate in the sector.

Additionally, the ability of needle valves to provide finely tuned flow control is critical in sectors such as pharmaceuticals and life sciences. As manufacturers increasingly adopt modular microfluidic systems, the capability of needle valves to maintain precise flow rates becomes a pivotal factor influencing system performance. The integration of advanced technologies and optimization methods in valve design only augments their utility in complex applications. Furthermore, data indicate that regions like India are significantly investing in gas valve markets, anticipating a compound annual growth rate that underscores the expanding need for specialized flow control solutions, including needle valves, in diverse industrial applications.

Expert Reviews of the Leading Needle Valve Brands in 2025

As we venture into 2025, the demand for precision control in fluid systems has never been more critical, underscoring the importance of selecting the right needle valves for optimal performance. According to a recent report by MarketsandMarkets, the global needle valve market is projected to grow from $1.2 billion in 2023 to $1.8 billion by 2027, driven by advancements in industries ranging from oil and gas to pharmaceuticals. This growth highlights the significance of high-quality needle valves, which offer enhanced accuracy in flow regulation and ensure system integrity under various operating conditions.

Expert reviews of leading needle valve brands reveal innovative features and technologies that set them apart in the market. Brands like Parker Hannifin and Swagelok have introduced needle valves designed with advanced materials that provide exceptional durability and resistance to corrosive substances. In addition, their precision-engineered designs facilitate micro-flow management, with some models boasting flow control accuracy within ±0.5%. As industries continue to emphasize efficiency and reliability, selecting a needle valve from a reputable brand becomes essential for engineers and procurement professionals aiming to meet the stringent demands of fluid system applications in 2025.

Maintenance Tips for Ensuring Longevity of Needle Valves

Needle valves are critical components in fluid systems, allowing for precise control of flow rates and pressures. To ensure their longevity and optimal performance, regular maintenance is essential. One primary aspect is to inspect and clean the valve frequently, removing any debris that may obstruct its function. This not only prevents malfunctions but also extends the life of the valve.

Another maintenance tip involves checking the seals for any wear or damage. Over time, seals can deteriorate, leading to leaks. If any signs of wear are noticed, timely replacement is necessary to maintain system integrity. Furthermore, lubricating the valve components according to the manufacturer's specifications can prevent corrosion and ensure smooth operation.

In addition to these practices, it is also wise to regularly test valve functionality, especially after extended periods of inactivity. Just as with machinery, neglecting routine checks can lead to bigger issues down the line, resembling the need for servicing engines or fixing common tool breakdowns. By adhering to these maintenance tips, you can ensure that your needle valves operate effectively for years to come.

10 Best Needle Valves for Precision Control in Fluid Systems

This chart represents the flow control efficiency of the top 10 needle valves based on their maximum flow rate (L/min) and precision rating (scale of 1 to 10).

Related Posts

-

Top 10 Ball Valves for Industry Use: Key Features, Trends, and Market Insights for 2024

-

Exploring the Innovative Applications of Tube Fittings in Modern Engineering Solutions

-

Innovative Applications for Tubing Connectors in Modern Industries

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

-

Top 10 Hose Fittings You Need for Your Next Project

-

Why Tube Fittings Are Essential for 70% of Industrial Fluid Systems Efficiency