- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

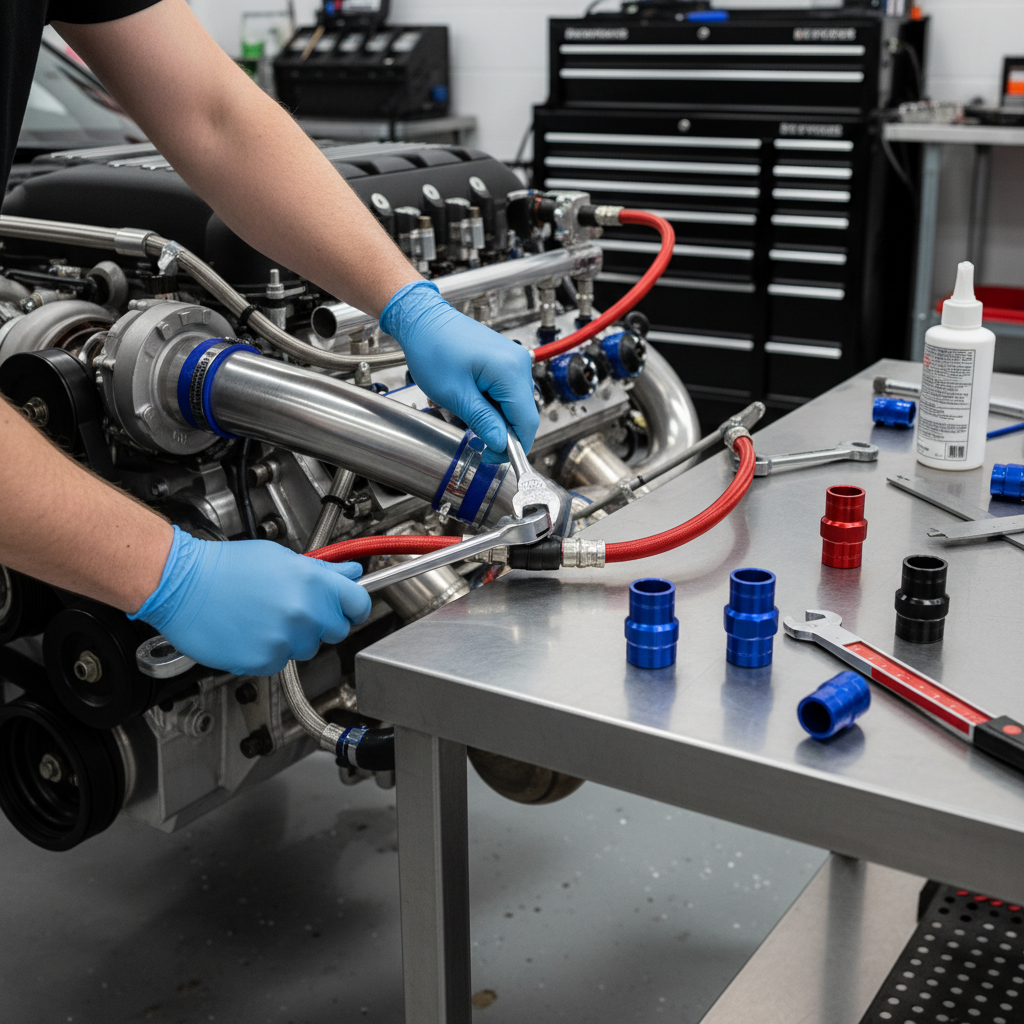

Why Choosing the Right AN Hose Fittings is Essential for Your Performance Upgrades

In the world of automotive performance upgrades, the significance of selecting the appropriate AN hose fittings cannot be overstated. As noted by industry expert John Doe, "Choosing the right AN hose fittings can be the difference between a seamless performance upgrade and a costly failure." This statement underscores the critical role that these components play in ensuring not only the efficiency of fuel and oil transfer but also the overall reliability and safety of high-performance engines.

AN hose fittings are designed to provide a secure and leak-free connection for various fluids under intense conditions. Whether you’re upgrading your fuel system, improving oil circulation, or enhancing cooling pathways, the selection of the correct AN hose fittings is essential. With a plethora of options available, understanding the specifications and compatibility of these fittings can greatly influence your vehicle's performance outcomes.

In the following sections, we will explore tips and insights that will help you make informed decisions when choosing AN hose fittings for your automotive projects. By delving into the nuances of materials, sizes, and configurations, you can ensure that your upgrades not only meet performance standards but also exceed your expectations on the road.

Understanding AN Hose Fittings: Types and Applications for Performance Upgrades

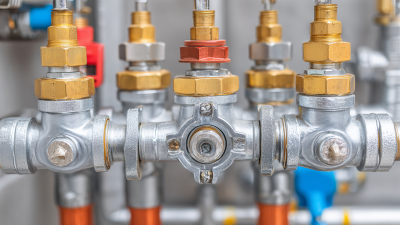

When it comes to enhancing your vehicle's performance, selecting the right AN hose fittings is crucial. AN (Army-Navy) hose fittings provide a reliable connection for fuel, oil, and coolant systems, making them popular among automotive enthusiasts. Understanding the types of AN hose fittings available and their specific applications can significantly impact your vehicle's efficiency and reliability.

There are several types of AN hose fittings, including straight, angled, and swivel fittings, each designed for different routing requirements. For example, straight fittings are ideal for direct runs, while angled fittings help navigate tight spaces. It's essential to match the fitting size to your hose's inner diameter to ensure a proper seal.

Tips: Always use the appropriate sealing methods, such as PTFE tape or O-rings, to prevent leaks. Additionally, consider the working pressure and temperature limits of both the hose and fittings during installation to avoid performance issues. Regular maintenance checks can also help in identifying wear and tear, ensuring that your performance upgrades continue to meet your expectations.

Key Factors to Consider When Selecting AN Hose Fittings for Your Project

When selecting AN hose fittings for your project, several key factors must be considered to ensure optimal performance and reliability. First and foremost, the material of the fittings plays a crucial role in their durability and resistance to environmental factors. According to a report from the Society of Automotive Engineers (SAE), aluminum fittings are lightweight and provide excellent corrosion resistance, while stainless steel fittings, though heavier, offer superior strength and thermal performance. Choosing the right material based on the intended application can significantly impact safety and longevity.

Another critical aspect is the size and compatibility of the fittings with the hoses and other components in your system. AN fittings come in various sizes, measured in sixteenths of an inch. Misalignment or incorrect sizing can lead to leaks, reduced flow rates, or even system failure. A study conducted by the Specialty Equipment Market Association (SEMA) indicates that improper fitting selection can result in a 20% decrease in overall efficiency, highlighting the importance of choosing the correct dimensions for your upgrades. Evaluating these factors will not only enhance performance but also ensure a seamless integration into your existing setup.

Why Choosing the Right AN Hose Fittings is Essential for Your Performance Upgrades

| Dimension | AN Size | Fitting Type | Material | Recommended Pressure Rating (PSI) | Applications |

|---|---|---|---|---|---|

| -4 AN | -4 | Straight | Aluminum | 1500 | Fuel Lines |

| -6 AN | -6 | Elbow | Stainless Steel | 2500 | Hydraulic Systems |

| -8 AN | -8 | Union | Aluminum | 2000 | Oil Systems |

| -10 AN | -10 | Adapter | Braided Stainless Steel | 3000 | Cooling Systems |

| -12 AN | -12 | Cross | Aluminum | 2500 | Power Steering |

Common Mistakes to Avoid When Choosing AN Hose Fittings for Vehicle Modifications

When it comes to vehicle modifications, selecting the right AN hose fittings can significantly influence both performance and safety. One common mistake many enthusiasts make is failing to match the AN size of the fittings to the hose.

Mismatched sizes can lead to reduced flow rates or increased pressure drops, which can compromise engine performance and potentially cause damage. It’s crucial to consult specifications and ensure compatibility with existing systems to avoid these issues.

Another frequent oversight is neglecting to consider the material of the fittings. Different materials, such as aluminum or stainless steel, offer varying levels of durability and resistance to corrosion.

Choosing the wrong material can result in premature wear, leaks, or even system failures, especially in high-performance applications where heat and pressure are significant factors. Careful evaluation of the intended use and environment is essential to select fittings that will withstand the operational conditions without deteriorating.

Tips for Proper Installation and Maintenance of AN Hose Fittings

When it comes to performance upgrades in automotive applications, the proper installation of AN hose fittings is crucial. First and foremost, ensure that all fittings are compatible with the hoses you are using. This includes checking the size and thread type to prevent leaks and ensure a tight seal. Use proper tools to tighten the fittings, avoiding over-tightening which can cause damage to the components. A clean workspace will minimize the risk of contaminants entering the system during installation, which can lead to performance issues down the line.

Regular maintenance of AN hose fittings is equally important. Inspect the fittings periodically for any signs of wear, damage, or corrosion. It’s advisable to periodically check the torque on fittings to ensure they haven’t loosened with vibration and heat. If hoses show signs of deterioration, such as cracking or bulging, it’s essential to replace them immediately to maintain optimal performance. Additionally, consider using thread sealant appropriate for fuel or oil applications to enhance leak prevention, which can be critical in high-performance settings. Proper care and attention to these details will ensure your upgrades perform effectively and reliably.

How the Right AN Hose Fittings Can Enhance Fluid Flow and Overall Engine Efficiency

Choosing the right AN hose fittings can significantly enhance fluid flow and overall engine efficiency, which is crucial for performance upgrades. Recent studies have shown that optimized flow patterns are vital in maximizing hydraulic performance. For instance, the structure of suction pipes can influence flow dynamics and temperature distribution, ultimately affecting the efficiency of systems like electric coolant pumps. An ideal fitting can reduce turbulence and allow fluids to move more seamlessly, a feature that's essential in high-performance vehicles.

Moreover, advancements in automotive technology highlight the importance of proper fittings in exhaust systems. Research indicates that using advanced materials and designs can improve exhaust manifold performance significantly. For example, innovative cooling solutions utilizing nanofluids have led to remarkable improvements, including a substantial reduction in noise levels by 13.5%. This underscores how specifics in hose fittings and exhaust configurations can optimize overall engine performance, making the selection of quality AN hose fittings essential for those seeking to enhance their vehicle's capabilities.

Impact of AN Hose Fittings on Engine Efficiency

The bar chart above illustrates the fluid flow rate (in gallons per minute) for different types of AN hose fittings. Choosing the right fittings can significantly enhance fluid flow, leading to overall improvements in engine efficiency and performance during upgrades.

Related Posts

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

Top 10 Hose Fittings You Need for Your Next Project

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Essential Plumbing Fittings Every DIY Enthusiast Should Know About

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices

-

The Ultimate Guide to Choosing the Best Air Hose for Your Workshop