- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

How to Choose the Right Pipe Plug for Your Plumbing Needs?

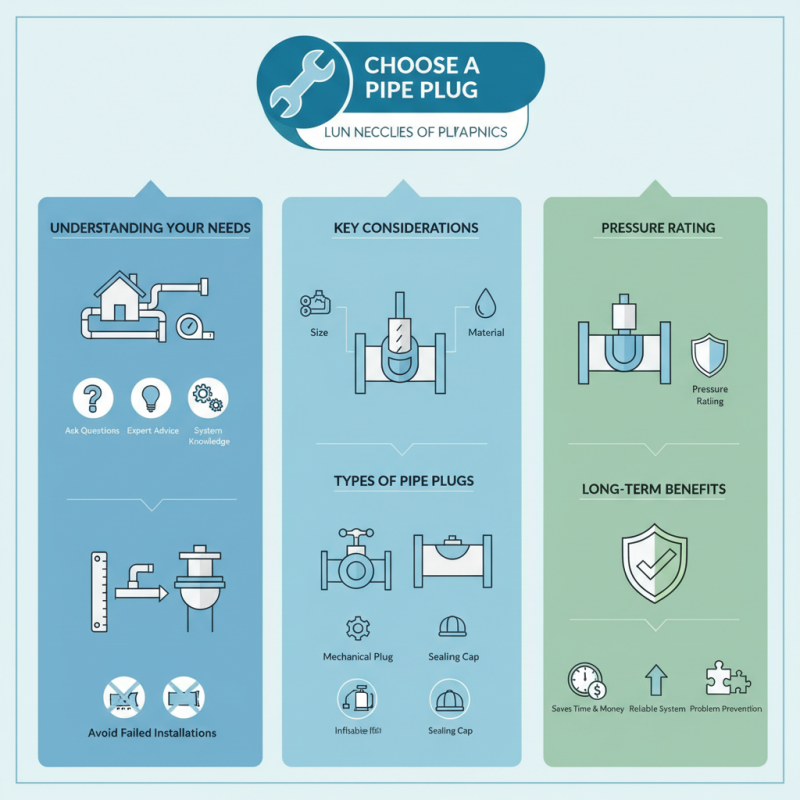

Choosing the right pipe plug for your plumbing needs can be a daunting task. With so many options available, making the right choice is crucial. According to plumbing expert John Smith, "The right pipe plug can save you time and money in the long run." His insight emphasizes the importance of selecting a suitable product to avoid unnecessary repairs.

Pipe plugs come in various sizes, materials, and designs. It’s essential to understand the specific requirements of your plumbing project. Consider factors such as pressure ratings and compatibility with other materials. Many people overlook these details, leading to failed installations. A missed measurement or wrong type can create complications.

Choosing a pipe plug is not just a technical decision; it also demands a thorough understanding of your system. Ask questions, seek expert advice, and don’t hesitate to test different options. Embracing this process can lead to better results. After all, investing time in choosing the correct pipe plug will pay off with a reliable plumbing system.

Understanding Different Types of Pipe Plugs for Plumbing Applications

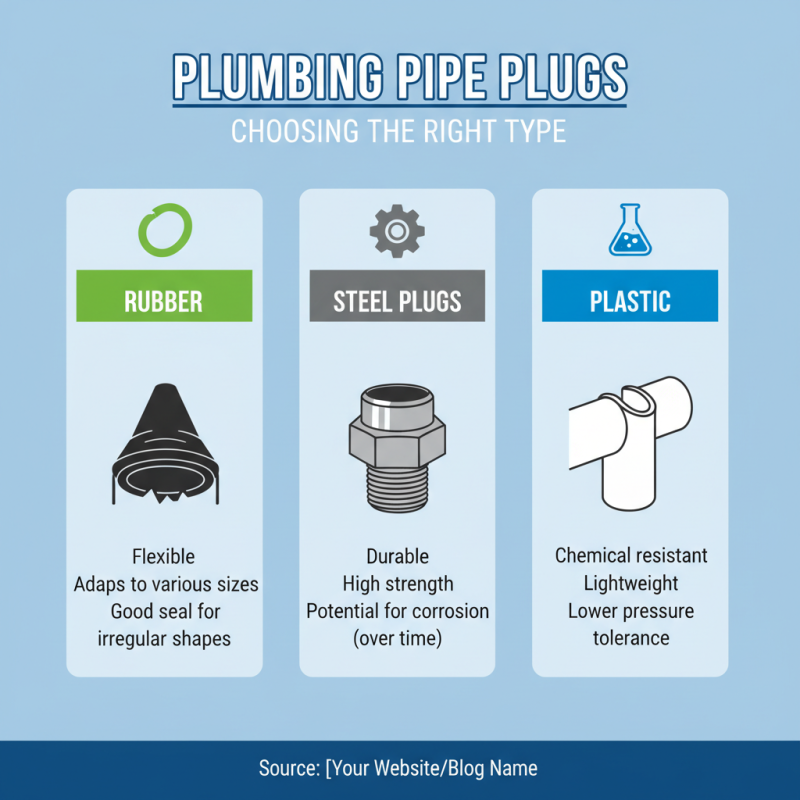

When it comes to plumbing, choosing the right type of pipe plug is crucial. Different applications require different plugs. For instance, there are rubber, steel, and plastic options. Each material has its own characteristics. Rubber plugs are flexible and can adapt to various pipe sizes. Steel plugs are durable but may corrode over time. Plastic plugs are resistant to chemicals but might not withstand high pressure.

Tips for selecting the right pipe plug include measuring the pipe size accurately. This ensures a snug fit. Also, think about the environment where the plug will be used. A plug that works well in one setting may not be suitable for another. Consider temperature variation and pressure levels.

Understanding the condition of the pipes is essential. Old, rusty pipes need special attention. They may require a plug that can provide an airtight seal. Not all plugs are the same. Some might leak under certain conditions. Think about the long-term effects of your choice. The right plug can save money on future repairs.

Factors to Consider When Selecting a Pipe Plug for Your Needs

When selecting a pipe plug, consider several important factors. The type of material is crucial. Different materials serve various purposes. For example, rubber plugs are flexible and can seal a range of pipe sizes. Metal plugs are durable but can be heavy and difficult to install. Think about the specific needs of your plumbing project.

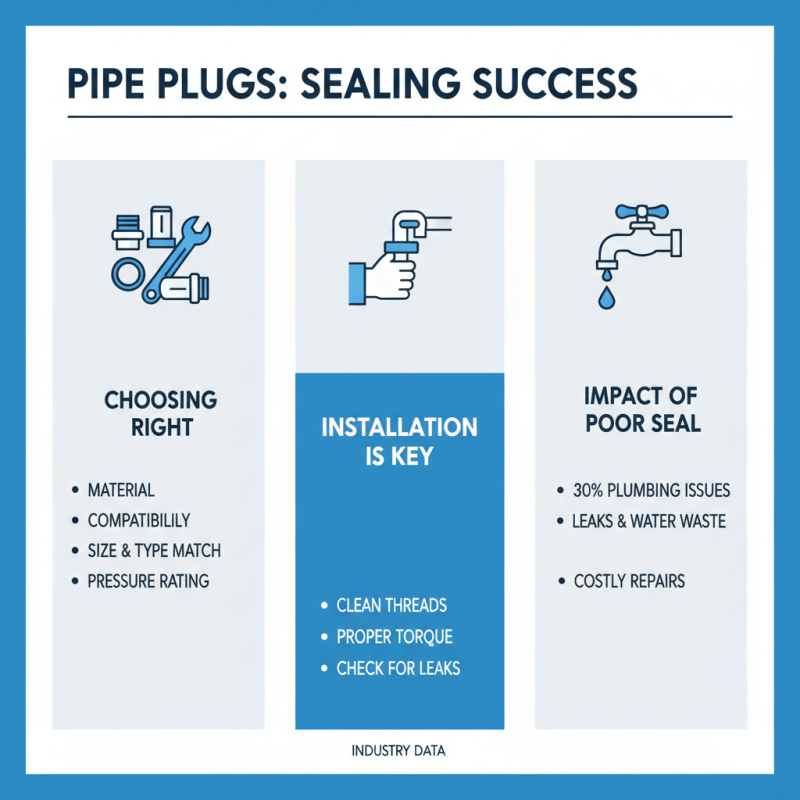

Another factor is the pipe size. Measure the diameter of the pipe accurately. A proper fit is essential to avoid leaks. If the plug is too small, it won’t seal. If it’s too large, it may not hold. Installation ease also matters. Some plugs can be tricky to set up, especially in tight spaces. This might lead to frustrations and delays.

Finally, consider the pressure rating. Some applications require plugs to withstand high pressure. Make sure the plug can handle the conditions it's being used in. If you overlook this detail, it could lead to a disaster. Always double-check specifications before purchase. Remember, a well-chosen pipe plug makes plumbing work smoother and more efficient.

Factors to Consider When Selecting a Pipe Plug

This chart illustrates the importance of various factors when selecting a pipe plug for your plumbing needs. Each factor is rated on a scale of 1 to 10 based on its relevance.

Sizing and Fit: How to Measure Pipe Diameter for Pipe Plugs

When selecting the right pipe plug, measuring the pipe diameter accurately is crucial. A poorly fitted plug can lead to leaks or even pipe damage. According to industry reports, improper fittings account for nearly 30% of plumbing issues annually. You must use calipers or a measuring tape to determine the outer diameter of the pipe. A snug fit is essential for sealing.

Be mindful of the fittings. The most common pipe sizes range from 1/2 inch to 6 inches in diameter. For instance, a 2-inch pipe will require a plug designed for that measurement. Furthermore, remember that pipes can have varying wall thicknesses. Industry guidelines suggest allowing for a little extra width in your measurements. This ensures the plug can accommodate any variations.

Perhaps you've encountered a scenario where you had the wrong size plug. Frustrating, isn't it? These mistakes can cause setbacks. It's important to double-check measurements before making a purchase. Don’t forget to consider the application. Different plugs are designed for various pressures and fluids. Therefore, understand the environment in which the pipe will operate.

How to Choose the Right Pipe Plug for Your Plumbing Needs?

| Pipe Material | Common Applications | Standard Pipe Diameter (inches) | Recommended Plug Type |

|---|---|---|---|

| PVC | Drainage, Venting | 1, 2, 3 | Expandable Plug |

| Copper | Water Supply, Heating | 1/2, 3/4, 1 | Threaded Plug |

| Cast Iron | Soil, Waste | 3, 4, 6 | Mechanical Plug |

| Steel | Industrial, Gas | 1, 2, 3, 4 | Welded Plug |

| Polyethylene | Irrigation, Water Lines | 1, 1.5, 2 | Compression Plug |

Material Choices: Choosing the Right Pipe Plug Material for Your System

Choosing the right pipe plug material is crucial for effective plumbing. Several materials are available, each with distinct properties. Common choices include

rubber,

plastic, and

metal.

These materials offer different levels of durability and resistance to temperature changes and chemicals.

Rubber pipe plugs are flexible and create tight seals. They're great for temporary applications. However, they may wear out faster than other materials.

Plastic plugs are lightweight and resistant to corrosion. They are suitable for many situations but can break under extreme pressure.

Metal plugs are robust and durable but can oxidize over time. They are often used in permanent installations.

Tip: Always assess the conditions your pipe plug will face. Temperature and pressure are key factors.

Selecting the right material can feel overwhelming. Think about your specific plumbing needs. For instance, if you are dealing with high temperatures,

avoid plastics. Reflect on how often you will need to install and remove the plug. If frequent access is needed,

rubber might be a better choice.

Tip: Keep a small inventory of various plugs on hand for emergencies. This can save time and stress when issues arise.

Installation and Maintenance Tips for Optimal Pipe Plug Performance

Choosing the right pipe plug can be tricky. Proper installation is key for optimal performance. According to industry data, improper sealing accounts for nearly 30% of plumbing issues. A poorly installed pipe plug can lead to leaks, wasted water, and more repairs.

Start by examining the material of your pipes. Plastic and metal pipes require different plug types. Ensure a snug fit to avoid any leaks during usage. It’s important to clean the pipe ends thoroughly before installation. Dirt and debris can affect the plug's effectiveness.

Maintenance is equally crucial. Regular inspections are needed. Look for signs of wear or corrosion. Industry reports suggest that up to 15% of pipe plugs fail due to lack of maintenance. Replacing old plugs can prevent future problems. Keep a close eye on the installation site after heavy usage. Small leaks can quickly escalate.

Related Posts

-

How to Choose the Right Pipe Plug for Your Plumbing Needs?

-

How to Choose the Right Needle Valves for Your Industrial Applications

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

What is a Gas Hose and How to Choose the Right One for Your Needs

-

How to Choose the Right Quick Connectors for Your Projects?

-

How to Choose the Right Hose and Fittings for Your Needs