- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

Why Are High Pressure Fittings Essential for Industrial Applications?

High pressure fittings play a crucial role in various industrial applications. These components are vital for maintaining the integrity of systems operating under extreme conditions. According to industry expert Dr. Emily Carter, "High pressure fittings are not just components; they are the lifeline of safe operations." This insight emphasizes their importance in preventing leaks and ensuring safety.

In industries like oil and gas, high pressure fittings are essential. They can withstand immense forces and temperatures. Depending on the application, few things are as critical as their reliability. When fittings fail, the consequences can be severe, leading to safety hazards and costly downtime. Regular inspection is necessary, yet we often overlook this aspect.

Moreover, the process of selecting high pressure fittings demands careful consideration. Material, size, and pressure rating must align with specific needs. Many professionals struggle with this. A rushed decision can result in failure. Thus, understanding the role of these fittings is vital for successful industrial operations. Proper training and awareness can make a significant difference.

Importance of High Pressure Fittings in Industrial Operations

High pressure fittings play a critical role in industrial operations. They are necessary for safe and efficient fluid transfer. According to the International Fluid Power Society, improper fittings can lead to 30% of fluid power system failures. This emphasizes their importance in maintaining system integrity.

In industries like oil and gas, high pressure fittings withstand extreme conditions. They must endure high temperatures and corrosive environments. A recent report from the American Society of Mechanical Engineers states that nearly 15% of all incidents involve leaking connections. This highlights the dire need for reliable fittings.

Installation practices can be as important as the fittings themselves. Many technicians overlook torque specifications. Inadequate torquing can lead to failure. The Fluid Power Journal points out that almost 40% of technician errors stem from improper installation. Clear guidelines and training are essential for minimizing risks and maximizing efficiency.

Importance of High Pressure Fittings in Industrial Operations

Types of High Pressure Fittings and Their Functional Roles

High pressure fittings play a crucial role in various industrial processes. They ensure strong and secure connections in systems that operate under high stress. There are several types of high pressure fittings, each with specific functions. Some common types include compression fittings, flanges, and threaded fittings. Each type has unique features that cater to different needs.

Compression fittings are designed for tight seals. They work well with tubes and pipes, preventing leaks. Flanges, on the other hand, provide a robust connection between two parts of a system. They allow for easy assembly and disassembly. Threaded fittings are versatile and easy to install, making them popular in many applications. These fittings can connect hoses and pipes efficiently.

Using the wrong type of fitting can lead to failures, hydraulic leaks, and safety hazards. It’s essential to select the appropriate fitting based on pressure and application requirements. Regular inspections are necessary, as wear and tear can affect performance. Keeping fittings well-maintained is vital for operational safety. Ensuring the right fitting is chosen will ultimately save time and costs in the long run.

Materials Used in High Pressure Fittings for Durability and Safety

High pressure fittings are crucial in various industrial settings. Their effectiveness largely depends on the materials used to manufacture them. Common materials include stainless steel, brass, and high-strength plastics. Each material offers unique advantages, contributing to durability and safety. Stainless steel is known for its strength and resistance to corrosion. Brass provides excellent malleability, making it suitable for intricate designs.

Choosing the right materials is vital. Not all applications require the same material. For extreme environments, special alloys may be necessary. However, this can lead to increased costs and complexity. Some fittings may also be over-engineered, which could be wasteful. Evaluating the specific needs of each application ensures the right balance between durability and safety.

It's essential to recognize that even with the best materials, failures can occur. Improper installation or maintenance can compromise the integrity of high pressure fittings. Regular inspections are necessary to prevent catastrophic failures. Sometimes, a flawed design can lead to issues that are not immediately obvious. This calls for continuous reflection and improvement in engineering practices.

Why Are High Pressure Fittings Essential for Industrial Applications?

| Material | Durability Rating | Max Pressure (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Stainless Steel | Excellent | 10,000 | -320 to 1500 | Oil & Gas, Chemical |

| Brass | Good | 5,000 | -40 to 400 | Waterworks, HVAC |

| Carbon Steel | Very Good | 15,000 | -20 to 700 | Hydraulics, Pneumatics |

| Monel | Excellent | 20,000 | -450 to 1200 | Marine, Chemical |

Application Scenarios Necessitating High Pressure Fittings

High pressure fittings play a crucial role in various industrial applications. They are designed to withstand significant pressure, ensuring systems operate smoothly. In oil and gas sectors, for example, these fittings transport fluids safely under immense pressure. Any failure in the system could lead to catastrophic results. This emphasizes the need for high-quality, reliable fittings.

In chemical manufacturing, high pressure fittings are equally vital. They support processes involving hazardous materials or extreme temperatures. Operators often face tough decisions due to safety concerns. A small leak can have dangerous consequences. Proper fittings reduce the risk of accidents, making safety a priority in plant operations.

Water treatment facilities also rely on high pressure fittings. They handle water filtration at high volumes, ensuring clean water supply. However, the physical stress on these fittings can be challenging. Regular inspections and maintenance are essential. This continuous care helps avoid equipment failures that could disrupt service. Fitting quality directly impacts system longevity and efficiency, making them indispensable in these scenarios.

Maintenance and Inspection Practices for High Pressure Fittings

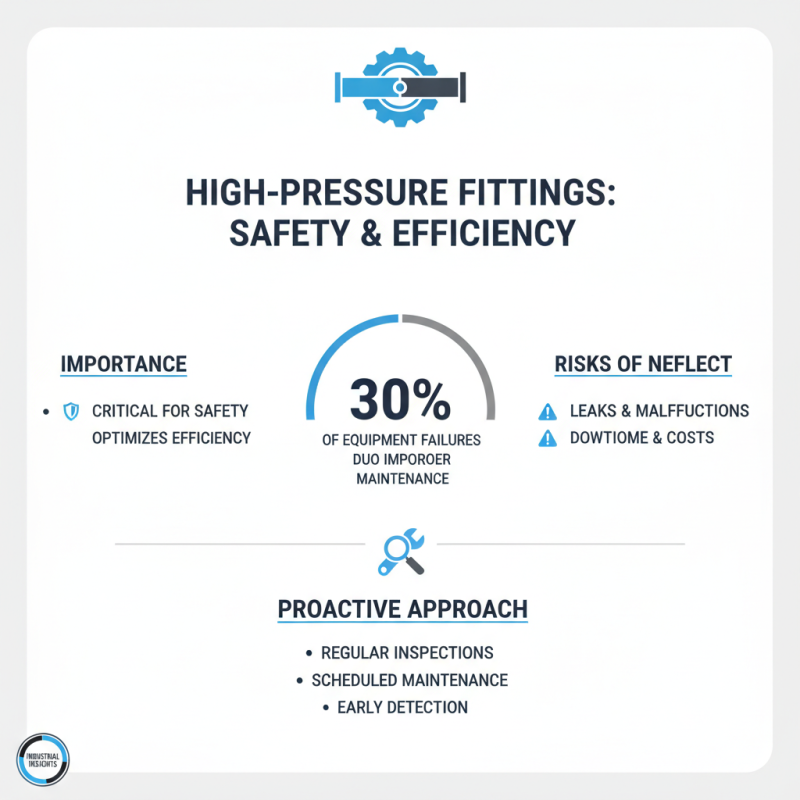

High-pressure fittings are critical in ensuring safety and efficiency in industrial applications. However, regular maintenance and inspection practices are often overlooked. Research indicates that nearly 30% of equipment failures occur due to improper fitting maintenance. This highlights the importance of a proactive approach to managing these components.

Routine inspections should focus on visible wear, corrosion, and leaks. Experts recommend establishing a schedule that aligns with operating conditions. For example, a facility operating at 5,000 psi may require biannual inspections. Conversely, systems under moderate pressure might only need annual checks. Utilizing pressure gauges regularly can also prevent catastrophic failures.

It's concerning that only about 50% of operators adhere to best practices in maintaining high-pressure fittings. This negligence can lead to costly downtime and safety hazards. Reports show that non-compliance with maintenance regulations increases risks by 40%. Implementing thorough training programs is vital to enhance employees' awareness. By fostering a culture focused on diligent inspection and upkeep, industries can improve both safety and productivity.

Related Posts

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

The Ultimate Guide to Choosing the Best Air Hose for Your Workshop

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

Top Gas Valves for Home and Industrial Use You Need to Know

-

How to Choose the Right Pressure Fittings for Your Plumbing Needs

-

Innovative Applications for Tubing Connectors in Modern Industries