- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

7 Essential Tips for Choosing Gas Fittings: Safety Standards and Best Practices

In the world of gas fittings, ensuring safety and compliance with industry standards is paramount. As technology and regulations evolve, it becomes increasingly important for both professionals and homeowners to stay informed about the best practices when it comes to selecting gas fittings. Industry expert John Carter, a renowned safety engineer with over 20 years of experience in the gas fitting sector, emphasizes, "Choosing the right gas fittings is not just about functionality; it’s about safeguarding lives and properties."

With the rising need for energy-efficient solutions and the growing complexity of gas systems, understanding the essential criteria for gas fittings selection has never been more critical. Whether you are upgrading your existing systems or starting fresh, it is crucial to consider factors like material compatibility, pressure ratings, and adherence to local safety regulations. By adhering to these best practices, individuals and businesses can ensure that their gas installations are not only efficient but, more importantly, safe. This article delves into the seven essential tips that will guide you in making informed choices about gas fittings, paving the way for a secure and reliable gas supply in any setting.

Understanding Gas Fittings: Key Terminology and Types

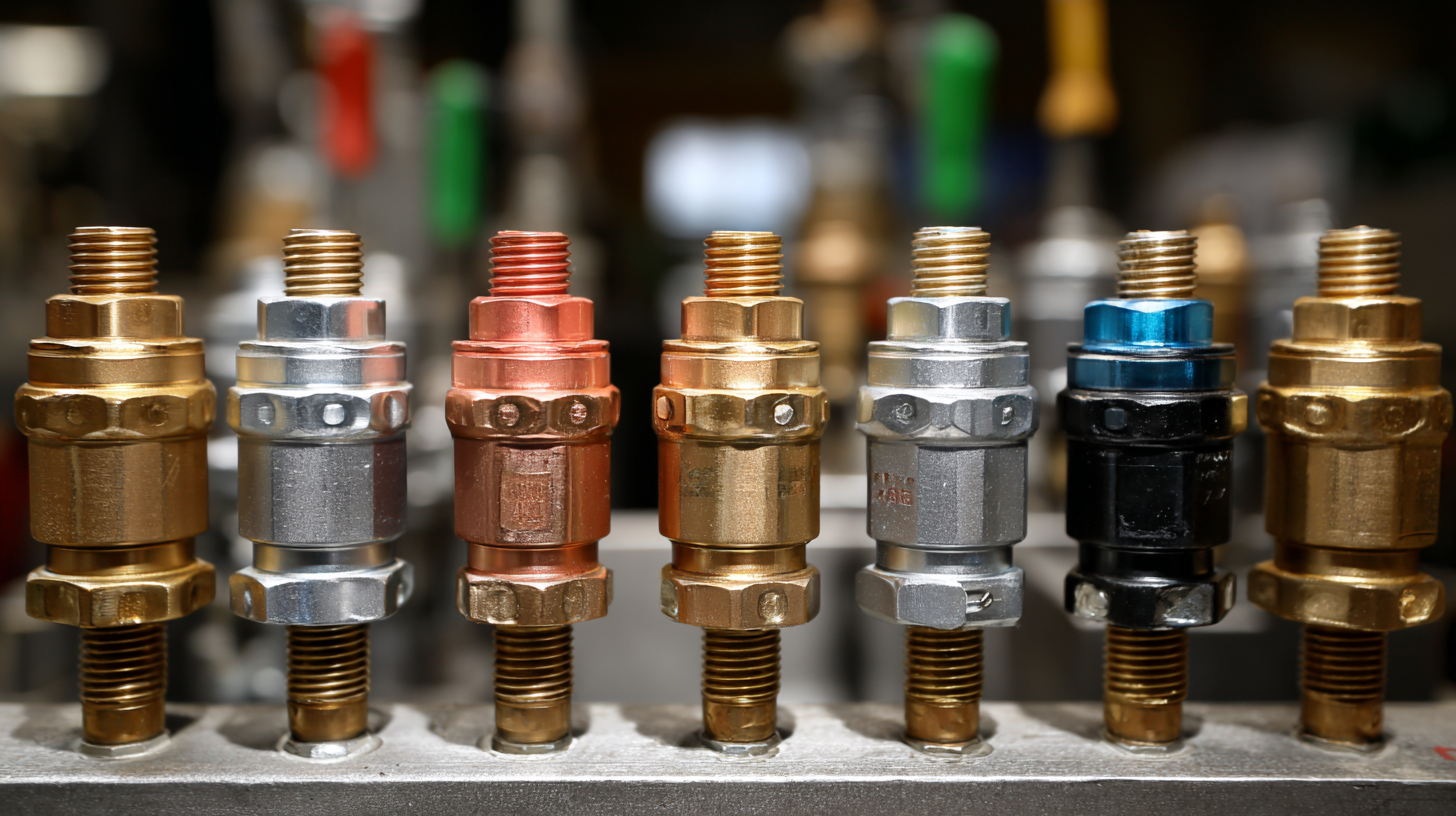

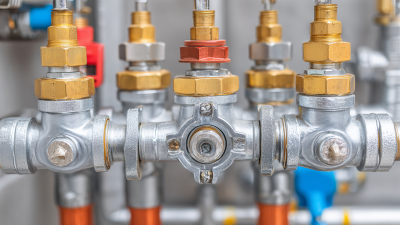

When it comes to understanding gas fittings, it's essential to familiarize yourself with key terminology and the various types available in the market. Gas fittings are integral components that connect gas pipelines to appliances, ensuring a secure and efficient flow of gas. Common terminologies include “couplings,” which allow two pipes to be joined, and “elbows,” which facilitate directional changes in piping. It's also important to understand the difference between types of fittings, such as those made from copper, brass, or plastic, each offering unique properties suited for specific applications.

Moreover, recognizing the different types of gas fittings is crucial for safety and functionality. For instance, connectors are used to join gas appliances to their supply lines, while valves control the flow and pressure of gas within a system. Additionally, adaptors help in transitioning between different pipe sizes or types. Familiarity with these fittings not only aids in compliance with safety standards but also enhances the reliability of any gas installation, thereby reducing the risk of leaks or accidents. Understanding these aspects can empower users to make informed decisions when selecting gas fittings for their needs.

Safety Standards to Look for When Choosing Gas Fittings

When selecting gas fittings, adhering to safety standards is paramount to ensure not only performance but also the safety of users. The primary safety standards to consider include those established by organizations such as the American National Standards Institute (ANSI) and the National Fire Protection Association (NFPA). These organizations provide guidelines that cover materials, design, and performance requirements for gas fittings. It is essential to verify that the fittings meet these standards, as failure to do so can lead to hazardous leaks or system failures.

Furthermore, when evaluating gas fittings, it is crucial to look for certifications from recognized bodies like Underwriters Laboratories (UL) or the Canadian Standards Association (CSA). These certifications indicate that the products have undergone rigorous testing and are compliant with the necessary safety protocols. Additionally, inspecting the material composition of the fittings—ensuring they are constructed from durable, corrosion-resistant materials—adds an extra layer of safety, reducing the risk of deterioration over time. By prioritizing these safety standards and certifications, consumers can make informed choices that protect both their property and well-being.

Best Practices for Installing and Maintaining Gas Fittings

When it comes to installing and maintaining gas fittings, following best practices is crucial to ensure safety and reliability. First, it is essential to select high-quality materials that comply with industry standards. Look for fittings made from durable materials like brass or stainless steel, which offer superior resistance to corrosion and wear. Ensure that all fittings are compatible with the specific type of gas being used—natural gas or propane—as this can greatly influence both performance and safety.

Proper installation techniques are equally important. Always follow the manufacturer's guidelines and ensure that all connections are tight and secure, using appropriate tools to prevent leaks. When testing for leaks, utilize a soap solution rather than an open flame, as this is a safer approach. Additionally, regular maintenance checks should be scheduled to inspect for any signs of wear, corrosion, or gas leaks. Implementing a routine examination of gas fittings not only enhances safety but also extends the lifespan of the system, safeguarding both property and individuals in the vicinity.

Common Mistakes to Avoid When Selecting Gas Fittings

When selecting gas fittings, it’s essential to avoid common mistakes that can jeopardize safety and efficiency. One significant error is opting for fittings that do not meet safety standards. According to the National Fire Protection Association (NFPA), approximately 58% of gas-related incidents are due to improper fittings and installation. Ensuring that your fittings comply with relevant standards, such as ANSI and ISO, can significantly reduce the risk of hazardous situations.

Another common pitfall is choosing the wrong size or type of fitting for your specific application. This often leads to leaks or pressure drops, creating potential fire hazards. Industry experts recommend always consulting manufacturers’ specifications and using tools like pressure gauges to ensure you’ve selected the correct fitting.

To assist in your selection process, here are some essential tips:

- Always prioritize quality over price, as cheaper fittings may compromise safety;

- Request certifications and test reports when buying from suppliers;

- Check for compatibility with your gas system to prevent installation issues.

How to Identify Quality Gas Fittings: Features and Certifications

When selecting gas fittings, understanding their quality is paramount to ensure safety in your home. Quality gas fittings should meet specific standards and certifications that indicate their reliability and durability. Look for fittings that are marked with relevant safety certifications, such as those from recognized authorities, to ensure they comply with safety regulations. Additionally, high-quality fittings often feature strong, corrosion-resistant materials that can withstand the demands of gas transportation.

Tips for identifying quality gas fittings include examining the manufacturer's reputation and checking for any industry-specific accreditations. Furthermore, the design of the fitting plays a crucial role; look for features like secure threading and robust seals that can prevent leaks. Always ensure that the fittings you choose are compatible with your gas system to minimize any risks associated with incorrect installations. Remember, investing time in selecting the right gas fittings is essential for safeguarding your property and ensuring the well-being of your household.

Related Posts

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

-

Essential Plumbing Fittings Every DIY Enthusiast Should Know About

-

How to Choose the Right Gas Hoses for Your Needs: A Comprehensive Guide

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project