- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

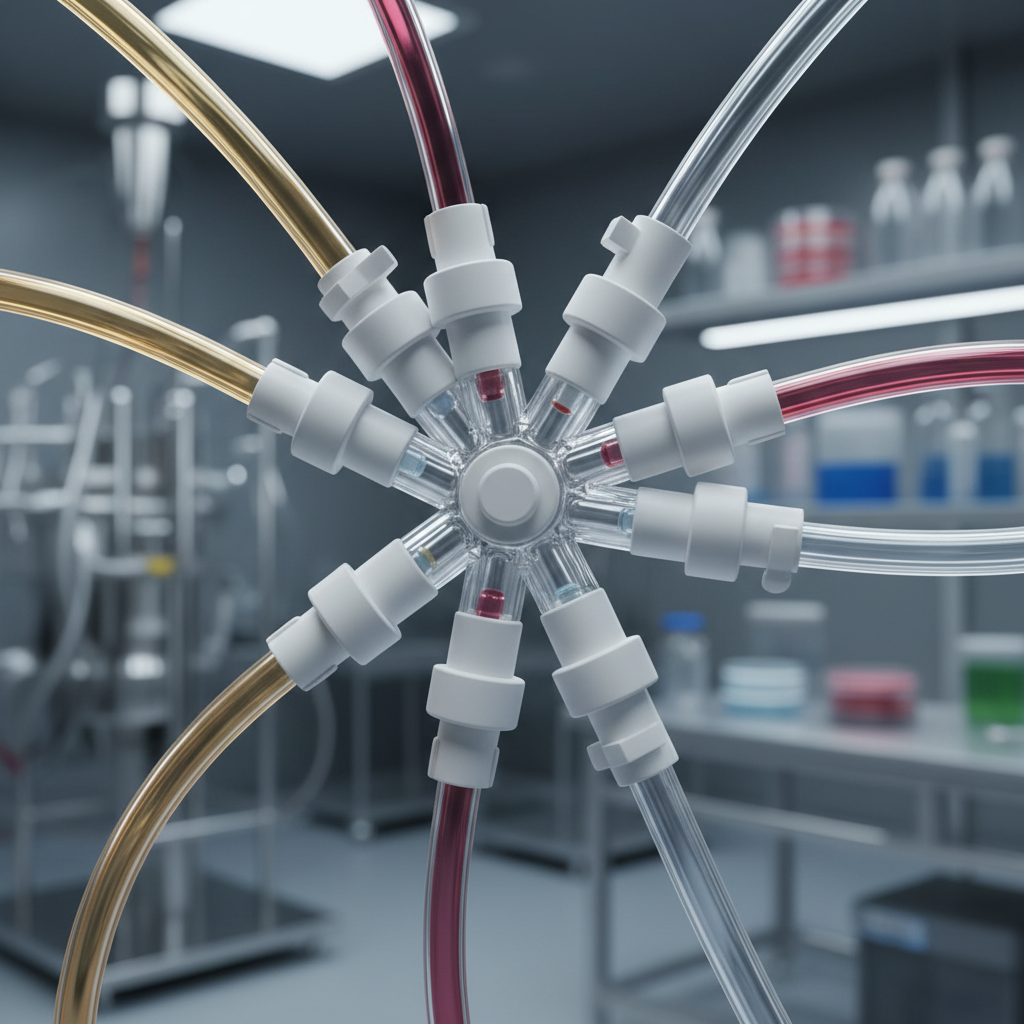

Why Tubing Connectors are Essential for Optimal Fluid Management Systems

In the world of fluid management systems, the significance of tubing connectors cannot be overstated. According to Dr. Emily Carter, a renowned expert in fluid dynamics, "The efficiency of a fluid management system hinges on the reliability of its tubing connectors." This statement encapsulates the core function of tubing connectors, which serve as the vital link that ensures the seamless flow of liquids in various applications, from industrial processes to medical devices.

As we delve into the intricacies of effective fluid management, we uncover how the choice and maintenance of tubing connectors are essential for optimizing system performance. The right connectors not only enhance fluid flow but also minimize the risk of leaks and other operational issues. This makes them critical components in achieving the desired outcomes in any fluid dynamics application.

The upcoming exploration of the "2025 Top 5" tubing connectors will provide an overview of the best options available in the market, highlighting their unique features and advantages. Understanding these connectors is crucial for professionals seeking to implement optimal fluid management strategies that meet the evolving demands of the industry.

Importance of Tubing Connectors in Fluid Management Systems

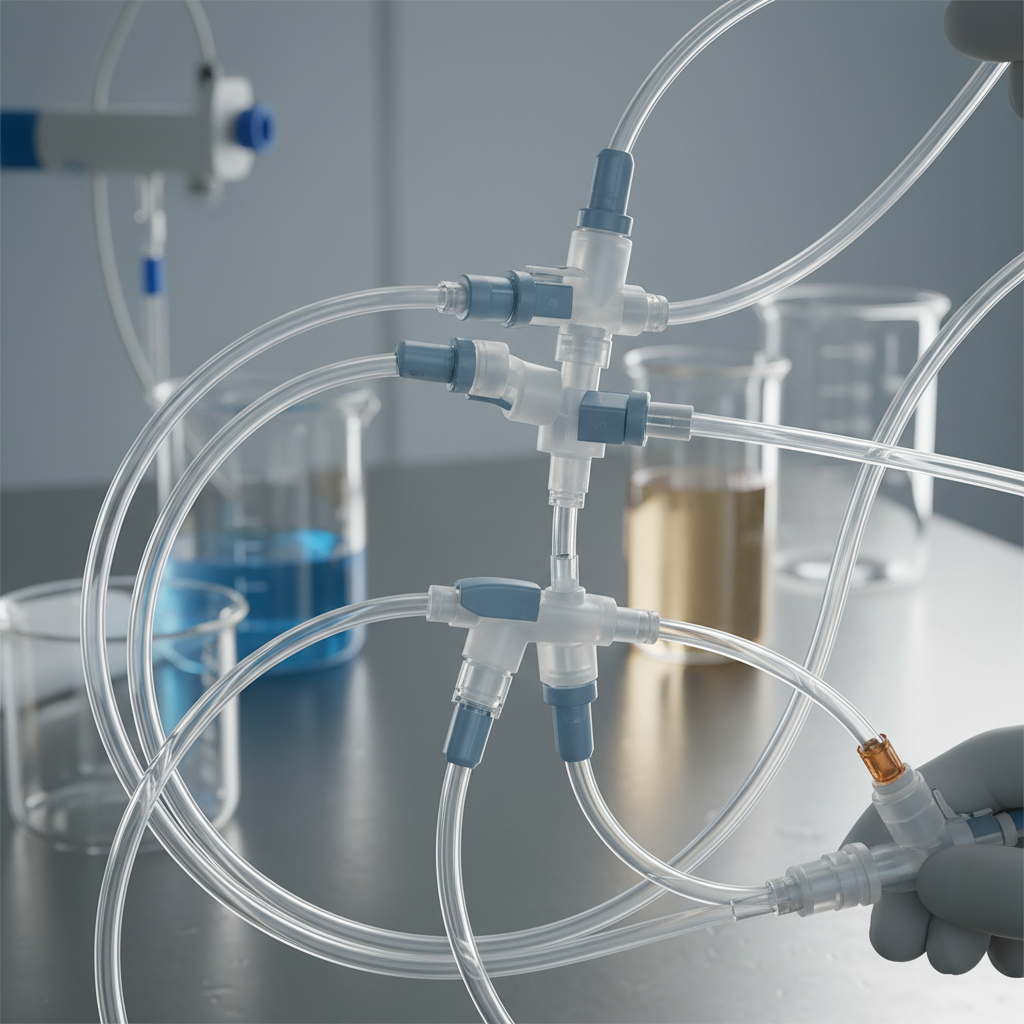

Tubing connectors play a crucial role in the efficiency and safety of fluid management systems, particularly in the medical and biopharma sectors. As the PVC pipe and fittings market is projected to reach USD 66.87 billion by 2030, the demand for reliable and effective fluid transfer mechanisms is increasingly evident. These connectors are essential for ensuring the integrity and sterility of fluid pathways, which is vital in applications like cell therapy manufacturing where contamination could compromise therapeutic efficacy.

In the context of complex manufacturing environments, the choice of tubing and its connectors can significantly impact operational efficiency. Studies highlight the unique requirements across different sectors; for instance, the transfer of fluids in cell therapy manufacturing necessitates the use of specialized aseptic connectors to maintain sterility. Additionally, the Fluid Conveyance Systems Market is expected to expand significantly, emphasizing the need for advanced materials and designs to mitigate risks such as water hammer, a phenomenon caused by rapid pressure changes in pipelines. With the ongoing advancements, suppliers are continuously innovating to meet these diverse demands, reinforcing the integral role of tubing connectors in fluid management systems.

Key Features of High-Quality Tubing Connectors

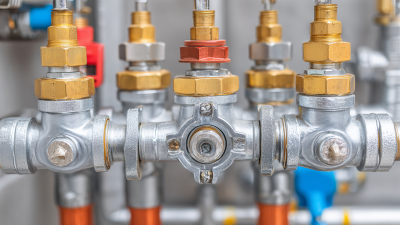

High-quality tubing connectors are pivotal in ensuring the efficiency and reliability of fluid management systems. One of the key features that distinguish superior connectors is their material composition. Premium connectors are often crafted from durable, corrosion-resistant materials like stainless steel or reinforced plastics. These materials not only enhance longevity but also provide the necessary strength to withstand high pressures, reducing the risk of leaks and failures in critical applications.

Another essential aspect is the design and compatibility of tubing connectors. High-quality connectors typically come with precision-engineered fittings that ensure a secure and leak-proof connection to various types of tubing. This compatibility is crucial, as it allows for seamless integration within a fluid management system, optimizing the flow rate and minimizing turbulence. Additionally, user-friendly designs with easy-to-use locking mechanisms streamline installation and maintenance, further contributing to operational efficiency and safety in fluid handling applications.

Why Tubing Connectors are Essential for Optimal Fluid Management Systems

| Feature | Importance | Material | Connection Type | Application |

|---|---|---|---|---|

| Leak-proof Sealing | Prevents fluid loss and contamination | PTFE (Teflon) | Barb Fitting | Chemical Processing |

| Durability | Ensures long-lasting performance | Stainless Steel | Compression Fitting | Food and Beverage |

| Compatibility | Allows integration with various systems | PVC | Push-to-Connect | Medical Applications |

| Flow Rate Optimization | Enhances system efficiency | Polyethylene | Quick Disconnect | Irrigation Systems |

| Temperature Resistance | Supports high-temperature fluid transfer | Silicone | Threaded Fitting | Pharmaceuticals |

Top Industries Benefiting from Advanced Tubing Connector Solutions

In various industries, advanced tubing connector solutions play a crucial role in ensuring efficient fluid management systems. The medical sector, for instance, relies heavily on these connectors for applications such as IV administration and fluid transfer. Precision and reliability are paramount in healthcare, as any leakage or disconnection can lead to severe consequences. Advanced tubing connectors that feature secure locking mechanisms and biocompatible materials enhance safety while minimizing the risk of contamination.

The chemical manufacturing industry also benefits significantly from advanced tubing connectors. These systems often handle aggressive chemicals and require connectors that can withstand high pressures and temperatures. Innovative materials and design improvements have led to connectors that not only ensure leak-free connections but also facilitate easy maintenance and reducing downtime. By integrating advanced tubing solutions, manufacturers can optimize productivity and adhere to stringent safety standards.

Innovations in Tubing Connector Technology for Fluid Efficiency

Innovations in tubing connector technology have significantly enhanced fluid efficiency in various industries. With the increasing demand for optimal fluid management systems, modern connectors now feature advanced materials and designs that minimize leakage and pressure loss. These innovations ensure a tighter seal and facilitate easier connections, ultimately improving the reliability of fluid systems. Manufacturers are now focusing on developing connectors that not only withstand extreme temperatures and pressures but also resist chemical corrosion, making them suitable for a broader range of applications.

Tips: When selecting tubing connectors, consider the specific fluid types and operating conditions of your system. Ensure compatibility with the materials used in your connectors, as this can prevent degradation over time. Additionally, regular maintenance can enhance their lifespan and overall system efficiency.

The rise of smart technology in tubing connectors is another exciting development. Connectors equipped with sensors can now monitor flow rates and detect issues in real-time, allowing for proactive maintenance. This technology not only increases operational efficiency but also aids in significantly reducing downtime, thereby enhancing productivity. Embracing these advancements in tubing connector technology positions businesses to thrive in an ever-evolving market landscape.

Tips: Keep an eye on industry trends and emerging technologies related to tubing connectors. Investing in training for your team on new technologies can further optimize fluid management systems and prevent costly errors.

Future Trends in Tubing Connectors and Their Impact on Fluid Management

The future of tubing connectors is poised for significant advancements that will directly influence fluid management systems. With the global fluid management systems market projected to grow from $12.5 billion in 2024 to $18.6 billion by 2030 at a 7.0% CAGR, there is a burgeoning demand for innovative solutions. This growth is indicative of the critical role that effective tubing connectors play in facilitating optimal fluid transfer, especially in bioprocessing and healthcare settings where precision and reliability are paramount.

Emerging design standards are leading to a reduction in the risk of misconnection in fluid management, further enhancing patient safety and operational efficiency. Additionally, recent trends in infusion and IV therapy highlight the increasing importance of single-use technologies, which are gaining traction as industries seek to elevate standards of hygiene and reduce cross-contamination risks. As the market matures, the integration of advanced materials and technologies in tubing connectors will likely offer substantial improvements in performance and adaptability, emphasizing their essential role in the evolution of fluid management systems.

Future Trends in Tubing Connectors and Their Impact on Fluid Management

Related Posts

-

Innovative Applications for Tubing Connectors in Modern Industries

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices

-

Top 10 Ball Valves for Industry Use: Key Features, Trends, and Market Insights for 2024

-

The Ultimate Guide to Choosing the Best Air Hose for Your Workshop

-

10 Best Needle Valves for Precision Control in Fluid Systems

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency