- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

What is a Gas Hose and How to Choose the Right One for Your Needs

Gas hoses are essential components in various applications where the transport of gas is required, spanning from domestic cooking to commercial industrial use. Understanding what gas hoses are and their specific functionalities is critical for ensuring safety and efficiency in gas-related tasks. These hoses are designed to handle different types of gases, such as natural gas, propane, and butane, and selecting the right one tailored to your particular needs can make a significant difference in performance and safety.

When choosing the right gas hose, several factors must be considered, including the type of gas being transported, the pressure requirements, and the environmental conditions in which the hose will be used. Additionally, the material composition of gas hoses plays a crucial role in their durability and compatibility with various gases. In this article, we will explore the essential aspects of gas hoses, provide insights into their distinctive features, and guide you on how to select the most suitable hose for your needs, ensuring a safe and seamless gas flow in your applications.

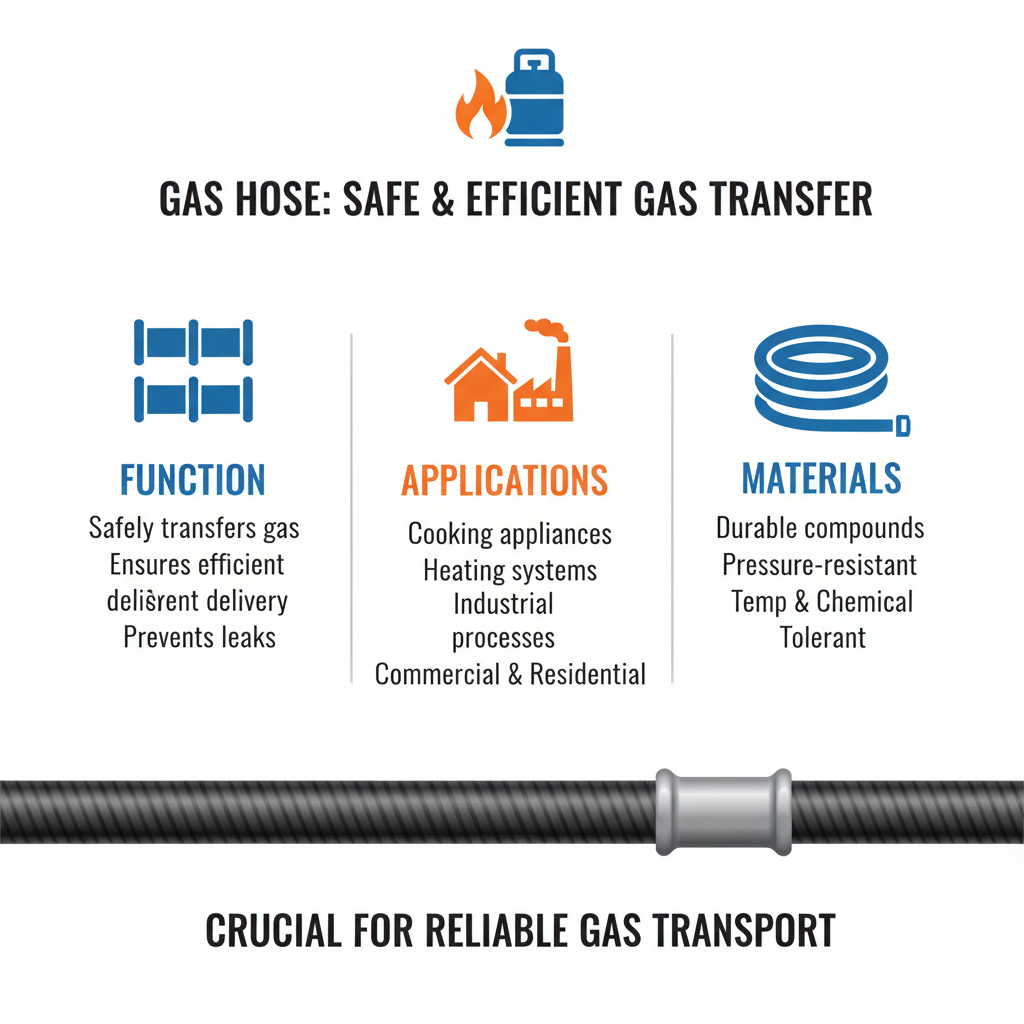

What is a Gas Hose and Its Primary Functions

A gas hose is a crucial component in various applications involving the transportation of gases, such as in cooking, heating, and industrial processes. Primarily, its function is to safely transfer gas from one point to another, ensuring that the gas is delivered efficiently and without leaks. Gas hoses are typically made from durable materials that can withstand pressure and exposure to different temperatures and chemicals, making them suitable for both residential and commercial use.

When selecting a gas hose, several factors need to be considered to ensure it meets specific needs. The type of gas being transported, the pressure rating, and the length of the hose are all critical variables. Additionally, the compatibility of the hose material with the gas type is vital to prevent degradation and ensure safety. Understanding these primary functions and considerations will help users choose the right gas hose suitable for their unique applications, thereby enhancing both functionality and safety in their respective environments.

Types of Gas Hoses and Their Specific Uses

Gas hoses are essential components in various industries, facilitating the safe and effective transfer of gases. The type of gas hose you select can significantly impact both efficiency and safety. Understanding the different types of gas hoses is crucial for making an informed decision tailored to your specific needs.

There are several common types of gas hoses, each designed for specific applications. For instance, rubber gas hoses are widely used for LPG applications due to their excellent flexibility and resistance to extreme temperatures. According to a report by the Gas Technology Institute, approximately 70% of gas application systems utilize rubber hoses because of their reliable performance and ease of installation. On the other hand, stainless steel braided hoses are often preferred in high-pressure environments, offering unparalleled durability and resistance to corrosion. This makes them ideal for industrial applications where safety and longevity are paramount.

Additionally, thermoplastic hoses are gaining traction due to their lightweight and kink-resistant characteristics. A study from the American Society of Mechanical Engineers indicates that thermoplastic hoses can reduce material handling injuries by up to 30%, promoting a safer working environment. When selecting the right gas hose, it's vital to consider factors such as the type of gas, pressure requirements, and environmental conditions to ensure optimal performance and safety.

Key Features to Consider When Choosing a Gas Hose

When selecting a gas hose, it is crucial to consider several key features to ensure safety and efficiency. First and foremost, the material of the hose should be compatible with the type of gas it will convey. According to industry standards, hoses made from rubber and thermoplastic materials are commonly utilized for propane and natural gas applications due to their excellent durability and resistance to environmental factors. The choice of material directly impacts the hose's lifespan; for instance, a quality thermoplastic hose can last up to 10 years under proper usage, minimizing replacement costs.

Another essential factor is the hose’s pressure rating. A gas hose must be able to withstand the operational pressure of the gas systems it connects. The British Standards Institution (BSI) recommends that hoses should have a working pressure at least 1.5 times higher than the maximum pressure in the system, ensuring a safety margin that reduces the risk of leaks or bursts. Additionally, the diameter of the hose is significant; larger diameters allow for higher gas flow rates, which can be critical in commercial applications, especially when equipment demands quick fuel delivery to maintain performance efficiency.

Gas Hose Selection: Key Features Comparison

This chart illustrates the crucial features to consider when selecting a gas hose. Each feature is rated on a scale of 1 to 10, presenting a clear view of what to prioritize when making a choice.

Safety Standards and Regulations for Gas Hoses

When selecting a gas hose, understanding the safety standards and regulations is crucial. Gas hoses are subject to strict guidelines to ensure safe operation, as outlined by organizations such as the American National Standards Institute (ANSI) and the National Fire Protection Association (NFPA). According to a report by the Gas Technology Institute, improper hose selection or maintenance is responsible for 20% of gas-related accidents, highlighting the importance of compliance with these standards.

To ensure safety, it’s essential to look for hoses that are marked with relevant certifications, such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association). These certifications indicate that the hose meets specific safety and performance criteria. A recent industry survey noted that only 30% of consumers are aware of these markings, which could lead to hazardous situations. Regular inspections and maintaining proper connections are also vital components of safety standards.

Tips:

- Always choose hoses that meet or exceed the standards relevant to your specific application.

- Regularly check for signs of wear or damage and replace hoses immediately if any issues are found.

- Educate yourself on the local regulations pertaining to gas hoses to ensure compliance and safety in your operations.

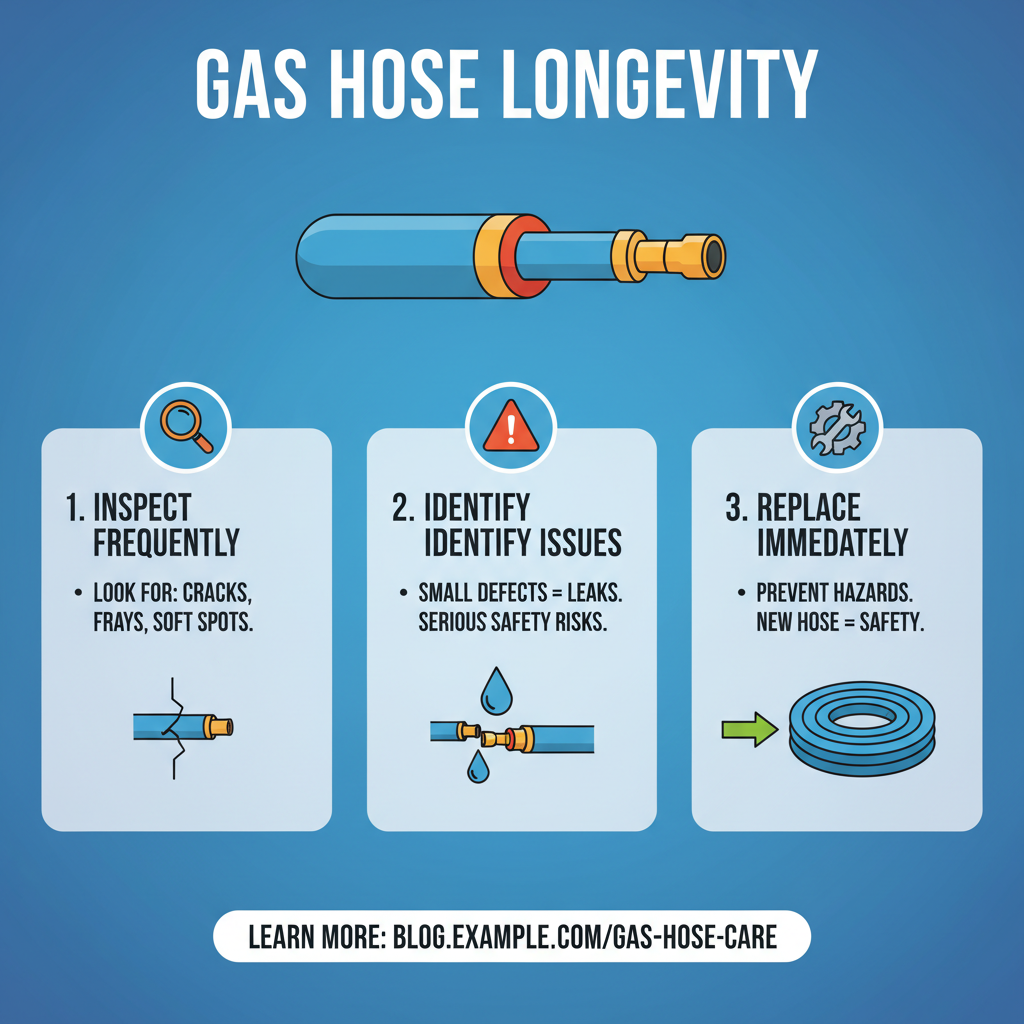

Maintenance Tips for Ensuring Longevity of Gas Hoses

To ensure the longevity of gas hoses, regular maintenance is essential. First and foremost, it is crucial to inspect the hoses frequently for any signs of wear and tear. Look for cracks, frays, or soft spots that could indicate the hose is compromised. Even small defects can lead to leaks, posing serious safety risks. If any issues are detected, replace the hose immediately to prevent potential hazards.

Additionally, proper storage of gas hoses can significantly extend their lifespan. Always coil the hoses loosely to avoid kinks, and store them in a cool, dry place away from direct sunlight and harsh weather conditions. High temperatures and UV exposure can degrade materials over time, leading to premature failure. Furthermore, when connecting or disconnecting hoses, handle them gently to prevent unnecessary stress on the fittings. By implementing these maintenance tips, you can ensure your gas hoses remain reliable and safe for use.

Related Posts

-

How to Choose the Right Gas Hoses for Your Needs: A Comprehensive Guide

-

Essential Plumbing Fittings Every DIY Enthusiast Should Know About

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

Why Tube Fittings Are Essential for 70% of Industrial Fluid Systems Efficiency

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices

-

10 Best Needle Valves for Precision Control in Fluid Systems