- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

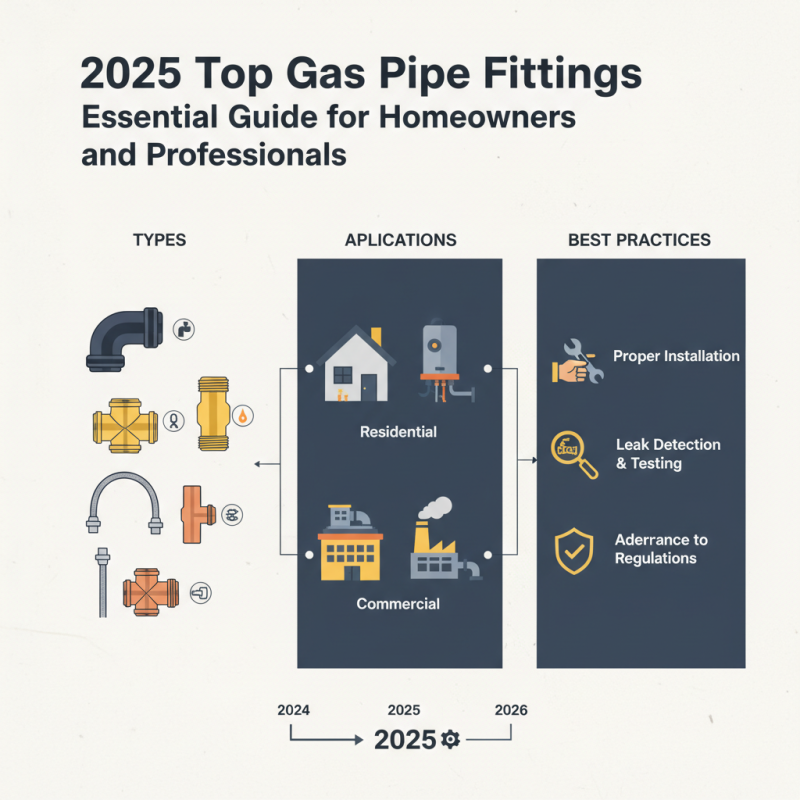

2025 Top Gas Pipe Fittings Essential Guide for Homeowners and Professionals

In the realm of residential and commercial plumbing, understanding gas pipe fittings is crucial for ensuring the safe and efficient transport of gas. As we look forward to 2025, homeowners and professionals alike must stay informed about the essential aspects of these fittings, which play a pivotal role in various gas-related installations and maintenance. This comprehensive guide aims to equip readers with the knowledge necessary to navigate the complexities of gas pipe fittings, providing insights into their types, applications, and best practices.

Whether you are exploring options for a new construction project or simply seeking to enhance your home’s gas infrastructure, grasping the fundamentals of gas pipe fittings can prevent costly mistakes and potential hazards. From the materials used to the specific regulations governing their installation, this guide will delve into everything you need to know about gas pipe fittings. Join us as we unravel the essential components that contribute to a safe and reliable gas system, ensuring that both homeowners and professionals can make informed decisions when it comes to gas installations and repairs in the years ahead.

Understanding Gas Pipe Fittings: Types and Uses for Homeowners

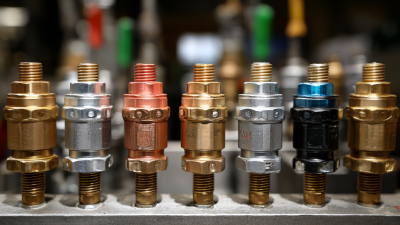

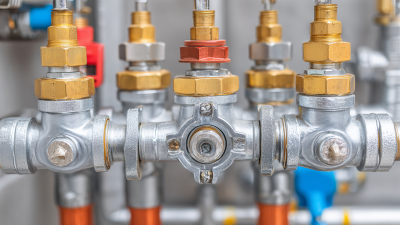

Gas pipe fittings are essential components in any gas distribution system, serving critical roles in both residential and professional settings. Understanding the various types of gas pipe fittings is crucial for homeowners and tradespeople alike, as these fittings ensure the safety and efficiency of gas delivery. Common types include elbows, tees, couplings, and reducers, each serving specific functions within the system. For instance, elbows facilitate directional changes in piping, while tees allow for branching connections, enabling gas flow to multiple appliances or fixtures.

In addition to their functional purposes, selecting the appropriate fittings depends on factors such as the type of gas being used, the pressure levels, and the specific requirements of the installation environment. For homeowners, using the right fittings not only enhances safety but also improves the overall efficiency and longevity of the gas system. Professionals must also pay careful attention to fitting materials—such as steel, brass, or nylon—to ensure compatibility with the pipe materials. Proper installation and maintenance of these fittings are critical to preventing leaks, which could lead to hazardous situations. By familiarizing themselves with the types and uses of gas pipe fittings, homeowners can make informed decisions and contribute to a safer living environment.

Essential Safety Considerations When Installing Gas Pipe Fittings

When it comes to installing gas pipe fittings, safety should always be the top priority for both homeowners and professionals. The use of proper materials is essential; selecting fittings that are specifically designed for gas applications can significantly reduce the risk of leaks and malfunctions. Always ensure that the fittings meet the relevant safety standards and are compatible with the type of gas being used. Additionally, employing techniques such as proper sealing and securing of fittings can further enhance the integrity of the installation.

Ventilation is another critical aspect of safety considerations. Adequate airflow can help prevent the buildup of gas should a leak occur. It’s important to install gas appliances and fittings in well-ventilated areas, ensuring that any potential escape routes for gas can effectively disperse fumes. Regular inspections and maintenance checks are also necessary to detect any signs of wear and tear, which could compromise safety over time. Ultimately, being vigilant about safety practices in gas pipe fitting installations not only protects property but also safeguards lives.

Choosing the Right Material for Gas Pipe Fittings: A Comprehensive Guide

When selecting the right material for gas pipe fittings, homeowners and professionals must consider several critical factors, including safety, durability, and compliance with industry standards. According to the American Gas Association, the most common materials used for gas piping include steel, copper, and polyethylene, each presenting distinct advantages and potential drawbacks. For instance, while steel is recognized for its strength and longevity, it requires proper corrosion protection to ensure a reliable performance over time. On the other hand, polyethylene, known for its resistance to corrosion and lightweight properties, has become increasingly popular in residential applications.

Tips: Always verify the local building codes before selecting materials for gas fittings. Compliance not only ensures safety but also prevents costly mistakes during installation. Furthermore, consulting updated guidelines from reputable sources like the National Fire Protection Association (NFPA) can provide insights into best practices and safety measures.

Another essential aspect of choosing gas pipe fitting materials is the specific application requirements. In high-pressure applications, intermediate grades of steel are often preferred due to their strength and ability to withstand pressure fluctuations. For low-pressure systems, copper fittings may suffice, though it’s essential to ensure compatibility with surrounding materials to avoid issues such as galvanic corrosion. Utilizing industry data can significantly enhance decision-making—research shows that proper material selection can reduce maintenance costs by up to 30% in gas distribution systems.

Tips: Consider life-cycle costs, not just initial expenses. Investing in high-quality materials might be more costly upfront but can yield substantial savings over the long term.

2025 Top Gas Pipe Fittings Essential Guide for Homeowners and Professionals

| Material | Common Uses | Advantages | Disadvantages | Recommended Pressure Rating |

|---|---|---|---|---|

| Steel | High-pressure gas lines | Durable, high strength | Susceptible to corrosion | Up to 150 psi |

| Copper | Residential gas piping | Corrosion resistant, easy to work with | Expensive compared to other materials | Up to 100 psi |

| PVC | Low-pressure applications | Lightweight, easy to install | Not suitable for high temperatures | Up to 60 psi |

| PE (Polyethylene) | Underground gas lines | Flexible, resistant to corrosion | Limited to low-pressure systems | Up to 100 psi |

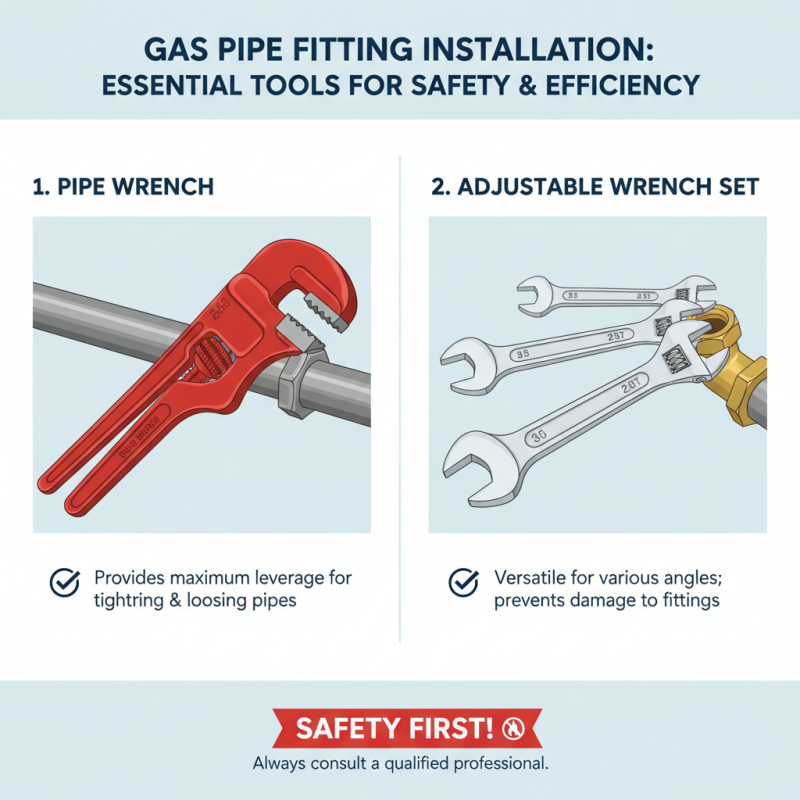

Tools Required for Proper Installation of Gas Pipe Fittings

Proper installation of gas pipe fittings is crucial for ensuring safety and efficiency in any gas system. To accomplish this, homeowners and professionals alike need to be equipped with the right tools. A sturdy pipe wrench is essential for gripping and turning pipes, providing the necessary leverage to secure fittings tightly. Additionally, a set of adjustable wrenches can assist in reaching difficult angles and tightening connections without damaging the fittings.

Measuring and cutting tools, such as a tape measure and a pipe cutter, are also vital for accurate installation. Ensuring that pipes are cut to the correct lengths minimizes the risk of leaks and ensures a snug fit. Furthermore, a deburring tool helps prepare the edges of cut pipes, preventing any sharp edges that could compromise the integrity of the fittings. Having adequate sealants and thread compounds specifically designed for gas applications is equally important, as they help in creating airtight seals, further enhancing the safety of the installation. With the right tools in hand, gas pipe installations can be executed efficiently and securely.

Maintenance Tips for Ensuring Longevity of Gas Pipe Fittings and Systems

Proper maintenance of gas pipe fittings and systems is crucial for both safety and longevity. According to a report by the American Gas Association, approximately 60% of gas supply issues arise from outdated or poorly maintained fittings. Regular inspections can identify potential leaks and other hazards before they escalate. Homeowners and professionals should check connections for corrosion and wear at least annually, ensuring that all fittings meet the required standards. Following the guidelines set by the National Fire Protection Association can enhance safety while extending the lifespan of these systems.

In addition to regular inspections, proactive maintenance practices such as proper sealing and avoiding excessive pressure in gas lines significantly contribute to the durability of gas pipe fittings. The Gas Technology Institute indicates that maintaining optimal pressure levels can reduce the incidence of fractures and leaks by up to 30%. Additionally, using appropriate lubricants on threads can prevent galling and enhance the integrity of the threaded connections. Overall, adhering to these maintenance tips will not only improve safety but also provide long-term cost savings through reduced repair and replacement needs.

Annual Maintenance Frequency for Gas Pipe Fittings (2025)

This chart illustrates the recommended annual maintenance frequency for various types of gas pipe fittings, emphasizing the importance of regular checks to ensure system longevity. The data indicates which fittings require more frequent attention.

Related Posts

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

-

7 Essential Tips for Choosing Gas Fittings: Safety Standards and Best Practices

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices

-

The Ultimate Guide to Choosing the Best Air Hose for Your Workshop

-

What is a Gas Hose and How to Choose the Right One for Your Needs

-

Why Choosing the Right AN Hose Fittings is Essential for Your Performance Upgrades