- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

Top Gas Valves for Home and Industrial Use You Need to Know

When it comes to both home and industrial applications, the importance of reliable gas valves cannot be overstated. These crucial components play a vital role in controlling gas flow, ensuring safety, and facilitating efficient operation across various systems. Choosing the right gas valves can significantly impact performance, safety, and cost-effectiveness in both residential and commercial settings.

In this overview, we will explore the essential types of gas valves available on the market, highlighting their functions, features, and the factors to consider when selecting them for specific applications. Whether you are a homeowner looking to optimize your gas appliances or a professional seeking efficient solutions for industrial processes, understanding the various options will help you make informed decisions. As we delve into the world of gas valves, we aim to provide valuable insights that will enhance your knowledge and assist you in finding the best solutions for your needs.

Essential Characteristics of Gas Valves for Home and Industrial Applications

When selecting gas valves for home and industrial applications, understanding their essential characteristics is crucial to ensure safety, reliability, and efficiency. Gas valves come in various types, designed to meet specific needs based on pressure, flow rate, and application. According to a report by the International Energy Agency (IEA), efficient gas flow control can reduce overall energy consumption by up to 30%, highlighting the importance of using suitable valves in both residential and industrial settings.

In home applications, gas valves typically feature safety mechanisms, such as automatic shut-off and sealing capabilities, to prevent leaks and ensure safe usage. These features are vital in maintaining the integrity of gas lines, as leaks can pose significant risks. Industry standards, such as those set by the American National Standards Institute (ANSI), emphasize the need for reliable performance under varying temperatures and pressures. In industrial contexts, valves often require more robust designs to accommodate larger flow capacities and extreme operational conditions, which can be supported by predictive maintenance technologies. A study from the American Gas Association revealed that proper valve selection and maintenance could prolong the lifespan of gas systems by approximately 20%, underscoring the value of investing in quality gas valves.

Understanding these characteristics not only aids in meeting regulatory compliance but also enhances operational efficiency across diverse applications. As the gas industry continues to evolve, focusing on advanced valve technology—such as smart valves equipped with IoT capabilities—will be essential for optimizing performance and maintaining safety standards in both home and industrial environments.

Top Gas Valves for Home and Industrial Use

This chart illustrates the essential characteristics of various gas valves used in home and industrial applications.

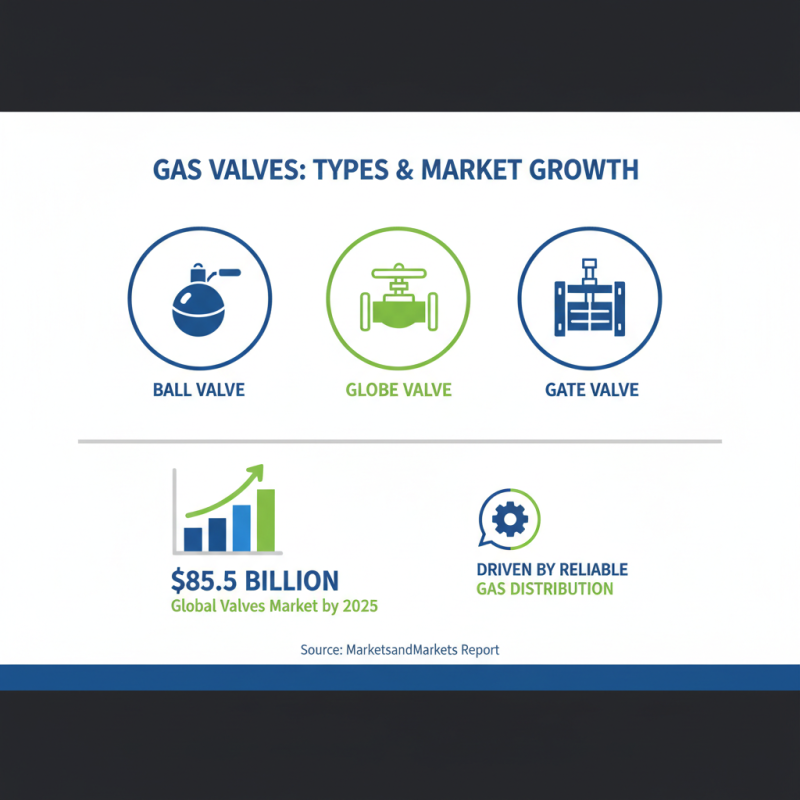

Types of Gas Valves: Ball, Globe, and Gate Valves Explained

When discussing gas valves, it's essential to understand the distinct types available, with ball, globe, and gate valves being the most common in both home and industrial applications. According to a report by MarketsandMarkets, the global valves market is expected to grow to $85.5 billion by 2025, driven in part by the increasing demand for reliable and efficient gas distribution systems.

Ball valves are favored for their ability to provide quick shut-off and low-pressure drop. They consist of a hollow ball that pivots to control flow, making them ideal for on/off applications. In contrast, globe valves are known for their excellent throttling capabilities. Their design features a spherical body, which allows for precise flow regulation, essential in systems requiring careful control of gas flow. The increased demand for natural gas in various countries has led to a corresponding rise in globe valve applications, particularly in situations where flow need to be adjusted rather than completely shut off.

Gate valves, characterized by their linear motion, are used when the goal is to either completely stop or allow fluid flow. They are designed to minimize pressure drop in pipelines, making them suitable for high-flow situations. According to the International Energy Agency, the rising emphasis on energy efficiency in industrial settings is leading to an increased application of gate valves, particularly in large pipelines that transport gas over long distances. Each valve type plays a crucial role in maintaining safety and efficiency within gas systems, showcasing the need for careful selection based on the specific requirements of the installation.

Key Considerations for Selecting Gas Valves for Different Uses

When selecting gas valves for various applications, whether in residential or industrial settings, several key considerations must be taken into account to ensure safety, efficiency, and compliance with industry standards. According to a recent report by the National Fire Protection Association (NFPA), the proper selection and installation of gas valves can significantly reduce the risk of accidents, citing that improper valve specifications are a leading cause of gas-related incidents.

One primary factor to consider is the pressure rating of the gas valve. Different applications demand specific pressure tolerances; for instance, residential gas appliances typically operate at lower pressures compared to industrial machinery, which may require valves rated for higher pressures up to 150 psi or more. Additionally, the valve material is crucial for durability and resistance to corrosive elements in the gas, with options including brass, stainless steel, and thermoplastics, which can each serve different environments effectively.

Another critical aspect is the valve type, which can vary from manual to automatic systems. Automatic shut-off valves, for example, are increasingly being adopted in industrial settings due to their ability to enhance safety by minimizing human error. The American National Standards Institute (ANSI) notes that the integration of such technology can lead to more than a 30% reduction in emergency responses related to gas leaks, thus emphasizing the importance of selecting the right type of valve for the intended use. Overall, careful consideration of these factors ensures not only compliance with safety regulations but also optimal performance of gas systems.

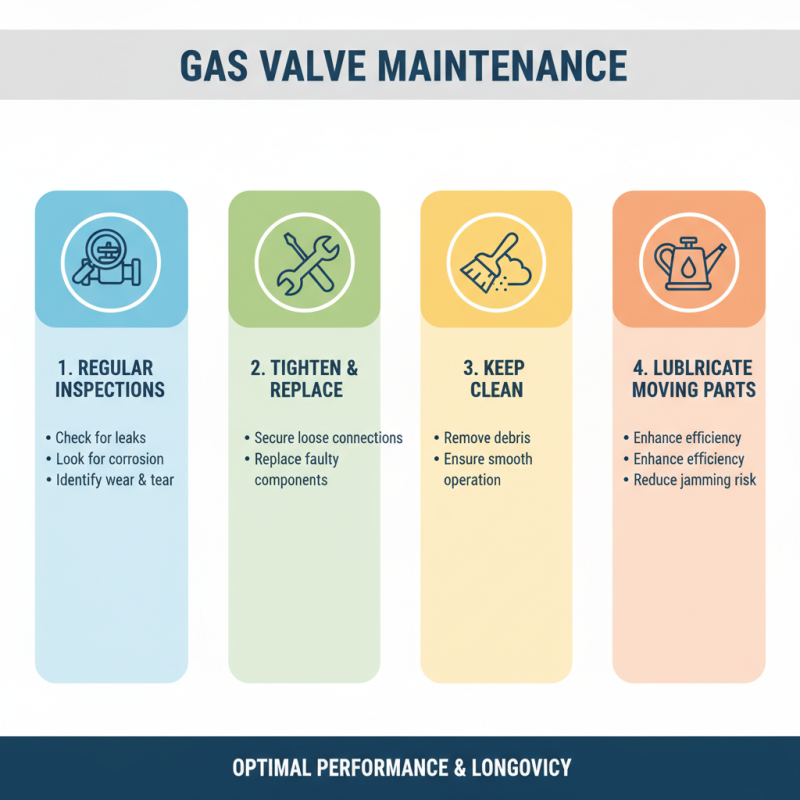

Maintenance Tips for Ensuring Optimal Performance of Gas Valves

Proper maintenance of gas valves is essential to ensure their optimal performance and longevity. Regular inspections should be conducted to check for leaks, corrosion, or any signs of wear. It is vital to tighten loose connections and replace any faulty components immediately to prevent potential hazards. Keeping the valve clean and free of debris will also facilitate smooth operation. Using a suitable lubricant on moving parts can enhance efficiency and reduce the risk of jamming.

Additionally, understanding the specific requirements of the gas valves used in your home or industrial setting is crucial. Operators should be familiar with the manufacturer's guidelines for maintenance schedules and operational limits. Implementing a routine maintenance plan can help identify minor issues before they escalate into significant problems. Moreover, educating all personnel who interact with gas systems about safety practices and maintenance procedures will promote a safer environment and enhance the reliability of gas valve operations.

Safety Features and Standards for Gas Valves in Residential and Industrial Settings

When it comes to gas valves for both home and industrial use, understanding safety features and standards is paramount. In residential settings, gas valves must comply with strict regulations to prevent leaks and ensure the safe operation of appliances. Key features include automatic shut-off mechanisms, which activate during pressure drops, and appropriate valve sizing to handle expected gas flow without risk of overheating or damage.

In industrial environments, the stakes are even higher. Beyond basic leak prevention, gas valves in these settings often incorporate advanced technologies like remote monitoring and emergency shut-off systems. These features help mitigate risks associated with high-pressure gas lines and provide operators with real-time data about their gas systems' performance.

Tips: Regular maintenance checks are essential. Ensure that your gas valves are routinely inspected and serviced, paying close attention to seals and connections to prevent leaks. Additionally, familiarizing yourself with local gas safety standards can greatly enhance your understanding of the necessary safety features required for different applications, whether at home or in an industrial facility.

Top Gas Valves for Home and Industrial Use

| Type of Gas Valve | Application | Safety Features | Compliance Standards |

|---|---|---|---|

| Manual Shut-off Valve | Residential | Visual indicators, Emergency shut-off | ANSI Z21.15, NFPA 54 |

| Automatic Shut-off Valve | Industrial | Flow detection, Remote monitoring | ISO 9001, ASME B16.34 |

| Pressure Regulating Valve | Residential & Industrial | Pressure relief, Adjustable settings | EN 334, AGA Cert. 6 |

| Solenoid Valve | Industrial | Electrical control, Fail-safe options | UL 429, API 607 |

| Ball Valve | Residential | Quick shut-off, Durable seals | ASTM F1476, NFPA 58 |

Related Posts

-

Top 10 Ball Valves for Industry Use: Key Features, Trends, and Market Insights for 2024

-

Top 10 Hose Fittings You Need for Your Next Project

-

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

-

The Ultimate Guide to Choosing the Best Air Hose for Your Workshop

-

Exploring the Innovative Applications of Tube Fittings in Modern Engineering Solutions

-

Essential Plumbing Fittings Every DIY Enthusiast Should Know About