- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

2026 Top Pressure Fittings Types You Need to Know?

Pressure fittings play a crucial role in various industries. They are essential for maintaining the integrity of fluid systems. Understanding the different types of pressure fittings is vital for engineers and technicians.

In 2026, the variety of pressure fittings is vast and diverse. Each type has its unique characteristics and applications. This knowledge can help prevent costly mistakes and ensure safety. However, not all fittings are created equal. Misjudgments in choosing the right pressure fittings can lead to leaks and system failures.

As industries evolve, so do the demands for better pressure fittings. Innovations continue to arise, yet some designs might not meet expectations. Reflecting on what works and what doesn’t is necessary for progress. This guide will explore the top pressure fittings types you need to know in 2026, highlighting both the successful designs and those that fall short.

The Importance of Understanding Pressure Fittings in Industrial Applications

Understanding pressure fittings is essential in industrial settings. They play a key role in maintaining system integrity. These fittings connect pipes, valves, and other components. A leak in a fitting can lead to significant downtime and safety hazards. Each type of pressure fitting serves a specific purpose, and selecting the right one matters.

Improper installation often results in leaks or failures. Many overlook the importance of proper torque specifications. Without adhering to guidelines, pressure fittings may not perform as expected. This can impact productivity and increase maintenance costs. Training staff on these fittings is crucial, yet often neglected. Awareness of the different types can prevent costly mistakes.

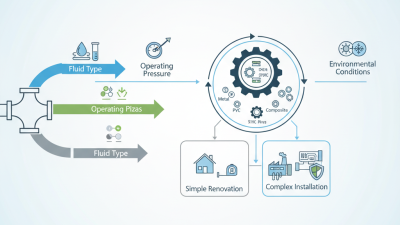

Choosing the correct material for pressure fittings is vital. Different environments require different materials. Steel, brass, and plastic all behave differently under pressure. Understanding these differences can affect the longevity of the system. Frequent inspections are needed to ensure everything functions correctly. Many industries struggle with this, leading to potential issues. Recognition of these factors can enhance operational efficiency.

Key Types of Pressure Fittings: Overview and Specifications

When discussing pressure fittings, it’s essential to understand the key types available. Pressure fittings are crucial in various industries, including oil and gas, manufacturing, and construction. Their specifications often dictate how effectively they function under high-pressure conditions.

There are several main types. For instance, threaded fittings have a simple design, providing reliability. Their ease of installation makes them popular. On the other hand, welded fittings offer superior strength. They are ideal for high-pressure applications but require more labor and skill to install.

Tips: Always consider the material compatibility. Some materials may not hold up under certain pressures. Regularly inspecting fittings can prevent leaks. According to a recent industry report, around 30% of failures are linked to improper fittings.

Another common type is flanged fittings, which provide a robust seal. These fittings are versatile and can withstand extreme conditions. However, they can be bulky, making them harder to integrate into tight spaces. As you select fittings, think about your specific needs carefully. Not all fittings are created equal; some may not perform well under stress.

Material Selection for Pressure Fittings: Impacts on Performance and Reliability

Material selection for pressure fittings is crucial in ensuring optimal performance and reliability. Different materials react differently under pressure and temperature. For example, stainless steel is known for its strength and corrosion resistance. However, it can be costly and may not be suitable for all environments.

On the other hand, plastic fittings are lighter and more cost-effective. But they may not withstand high pressures as well as metals. This trade-off can lead to faulty connections if not carefully evaluated. Some engineers overlook the long-term implications of material choices, leading to premature failures.

Additionally, factors like temperature variations and exposure to chemicals must be considered. Inadequate research on these aspects can result in serious safety issues. Inadequate attention to detail can compromise system integrity. It's critical to re-evaluate this process regularly, ensuring materials align with specific applications and safety standards.

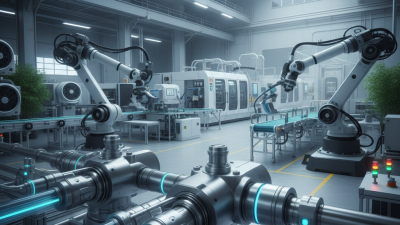

Trends in Pressure Fitting Technology: Innovations and Future Directions

The landscape of pressure fitting technology is rapidly evolving. Recent reports indicate a projected market growth rate of over 6% annually through 2026. This growth highlights the increasing demand for efficient piping systems across various industries, including oil and gas, water treatment, and HVAC.

Innovations in materials are at the forefront of these trends. For instance, advanced composite materials are now being used to enhance durability and reduce weight. This change can lead to improved performance under high pressure and temperature conditions. Additionally, strong focus is placed on developing corrosion-resistant fittings, which are crucial for longevity and safety in demanding environments.

Automation plays an essential role too. Smart monitoring systems integrated into fittings allow for real-time pressure and flow data. According to industry analysts, 50% of manufacturers are now investing heavily in IoT technology for this purpose. However, this shift raises questions about standardization and compatibility among different systems. As technology pushes forward, ensuring seamless functionality becomes a necessary consideration. The journey ahead holds promising possibilities but also significant challenges for manufacturers and users alike.

Safety Standards and Compliance for Pressure Fittings in Different Industries

Pressure fittings play a critical role in various industries. They ensure the safe transfer of fluids in systems like oil and gas, water management, and manufacturing. Compliance with safety standards is essential. These standards vary across regions and industries, affecting the design and selection of fittings.

In the oil and gas sector, for example, specific materials and designs are mandated. Safety inspections must occur regularly. In contrast, the water treatment industry focuses on corrosion resistance. Every fitting used must meet specific criteria to prevent leaks and ensure safety. Often, companies face challenges meeting these various standards.

Regulatory bodies enforce these rules, but enforcement can vary. Some industries lag behind, leading to potential risks. Manufacturers sometimes overlook minor details in compliance, which can have serious consequences. It’s vital to prioritize safety and regularly revisit standards to adapt to changes in technology and processes.

Related Posts

-

2025 Top Trends in Pressure Fittings for Industrial Applications

-

How to Choose the Right Pressure Fittings for Your Plumbing Needs

-

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

-

Why High Pressure Fittings Are Essential for Safe Industrial Applications

-

How to Choose the Right Pipe Plug for Your Plumbing Needs

-

How to Choose the Right Hose and Fittings for Your Needs